Suppliers of corrugated containers are in boxing matches, so to speak, slugging it out over who can out-green whom on fiber content: virgin vs. recycled. Consumer packaged goods companies, more than ringside observers, are the scorekeepers who decide the winners. No apologies for subjectivity are in order, though, because each packager should decide based on his or her own criteria.

But is the fight necessary? As an industry, corrugated is the pound-per-pound champ in sustainable packaging. No other material can weigh-in quite like it, tipping the scales as renewable, reusable, and recyclable. On the supplier side, blame the fighting on the nature of competition and the never-ending quest for an advantage. But, on the user side, some blame is deserved for the willingness to reduce sustainability decisions to a simple calculus, such as "if recycled content saves virgin resources, the more recycled content the better."

Avoiding too much of a good thing

First of all, it’s impossible to have a corrugated supplier industry based solely on 100% recycled fiber. Recycling damages fibers and shortens their lengths, thereby reducing the strength of the resulting box. That’s why most corrugated is comprised of less than a majority percentage of recycled fiber. More so, the number of times that fibers can be recycled before becoming useless is said to be around four (not that anyone has devised a reliable way of determining how many times individual fibers have been repulped)—another reason why the industry can’t wholly dispense with virgin fiber.

Beyond the aforementioned facts, the basic question of what is the proper percentage of recycled fiber is complicated by a number of considerations. The most basic is the definition of recycled fiber, for there are two waste sources: pre-consumer and post-consumer, the former from scrap fed back into the production process and the latter from households, businesses, institutions, etc. Pre-consumer is stronger, for reasons alluded to; however, post-consumer arguably saves more virgin fiber. Such distinctions are of limited value, however, when—as is often the case—the supplier only cites the percent of recycled fiber and not its sources.

Not that such disclosure would solve everything. For example, should a packager be willing to pay more for 30% pre-consumer content than for 30% post-consumer content? For that matter, two boxes of the same-percent post-consumer content can perform differently, if one’s content has been recycled more than the other’s. Yet, the buyer has no way of obtaining that information—the supplier doesn’t know—and, therefore, is unable to factor it into the price.

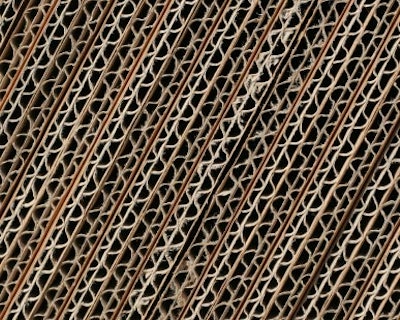

Never assume that any cited percent of recycled content is distributed uniformly throughout the sheet. Taking as an example single-wall construction (outer facing/flute/inner facing) corrugate, recycled content distribution can affect key performance measures. If the majority of the recycled content is in the facings, the result can be reduced bursting strength. If the majority is in the flute, the result can be reduced compression strength

Further complications arise from the freedom with which some suppliers are citing recycle percents—10, 30, 66, etc.—without any disclosure as to how such percents were calculated, whether on basis weight, for example.

Doing away with recycled content altogether in favor of 100% virgin fiber would simplify matters from engineering and design perspectives, but it’s not an option in these environmentally sensitive times, even if all the virgin fiber is sourced from certified, sustainably managed forests. Such a box, without compromise, could contain, protect, and communicate its contents, but wouldn’t eliminate end-of-life considerations.

Going all the way

The opposite of a box comprised of 100% virgin fiber is one of 100% recycled fiber, more specifically 100% post-consumer waste (PCW) fiber. However, given the multitude of vagaries associated with such a box, it is to be expected that users would report a variety of experiences, some decidedly bad. It is no small matter, since the corrugated shipping box is the central cog in the supply chains of most packagers, affecting costs and efficiencies throughout.

If the box is performing insufficiently, the analysis should proceed step-wise. If the box is a replacement of a “less-green” composition that had performed satisfactorily, and if the supply chain variables that impact performance have not changed, then the issue simply might be that the 100% PCW box is not up to the task. That box, as well as any supposedly green choice, should justify itself in costs and performance, on a systems basis. Why try to force a fit?

If, on the other hand, the packager believes the ability to tout a 100% PCW box has benefits worthy of further analysis, one consideration is whether the company has been too aggressive, a polite way of saying "too greedy." Has the company, for example, not contented itself with the PCW factor, but has pursued additional benefits through source reduction, i.e. ending up with a box lighter in weight than its predecessor? In our boxing analogy, this is the equivalent of a fighter dropping too much weight and coming into the ring too weak.

Also, investigate whether there is an adherence to best practices for palletizing. Such changes as eliminating overhang and under-hang, minimizing top void, and making sure that the pallet pattern stably interlocks reduce the strength requirements of the box.

Do not go overboard, determined to stay with a 100% PCW box beyond systems cost justification. For example, compensating for box weakness through higher Mullen or Edge Crush Test ratings, bulking up on interior dunnage, or even increasing the strength of the primary package should not combine to defeat the green benefits of recycled fiber.

When should you know?

It’s better to learn of the limitations of a box, whatever its composition, prior to committing to it. In a word, the box should be tested to ensure it will endure the hazards of the supply chain.

Actually, the challenge starts with the specification. A high degree of standardization is desirable, whether with a material specification based on a specific construction or a performance specification based on specific criteria. Standardization, however, is not the defining characteristic of recycled fiber. Suppliers responding to a material specification calling for, say, 30% recycled fiber content can vary considerably in their offerings. So too can suppliers responding to a performance specification requiring that the box meet specific functionalities.

The variability that characterizes virgin vs. recycled fiber discussions also has ramifications for the packager's quality assurance procedures. Can the same tolerances be held while increasing the recycled fiber content or must they be relaxed, and if so, by how much?

In all, decision-making for even the most inherently sustainable packaging choices is multifaceted. Appreciate that fact. Prepare for it, so as not to be blindsided, like the boxer who never saw the punch coming.

Before becoming a packaging consultant, Sterling Anthony worked for Fortune 500 food, healthcare, and automotive companies, and has taught packaging at the university level. He welcomes your comments by phone, 313/531-1875 or by e-mail, [email protected]. His Web site is www.pkgconsultant.com.