Welcome to Package This — your guide to packaging machinery & materials, produced by the Emerging Brands Alliance in conjunction with Packaging World and PMMI - the Association for Packaging and Processing Technologies.

Today’s episode covers packaging equipment for pre-made trays, cups, and bowls. To see the basics of packaging formats and the machinery that make them, see our Package This video series.

Pre-made trays, cups, and bowls are pre-formed and purchased from a supplier, ready to fill and seal. But some manufacturers prefer to form their own packaging before filling and sealing. Let’s break down the two options:

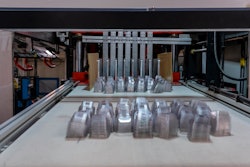

Thermoforming refers to the process of heating materials into the desired shape — typically blisters, bowls, trays, or clamshells. Integrated into a Thermoform/Fill/Seal machine, this process allows for flexibility, customization, and control over packaging and production.

With pre-made packaging, your suppliers handle material acquisition, product protection and sustainability considerations, and maybe even labeling. Choosing pre-made packaging may make sense for manufacturers who are initially producing fewer products. However, it may be more cost-effective at a certain point to make your own packaging from start to finish.

If you are experimenting with packaging formats, need flexibility, and are aiming for lower initial costs, pre-made tray/cup and bowl packaging equipment may be for you. Let’s jump into the different machine types that fall under this category and how they fit into a manufacturing line.

PRODUCT LOADERS put the product into the package. Loaders are customizable, and can come with embedded weight checkers, clean-in-place systems, and cut-off or suck-back nozzles. Their piston fillers can be pneumatic, mechanical, or servo-driven, depending on the viscosity of your product and how precisely you need product dispensed.

The Yamato MPD takes weighed product and deposits it into bowls or trays of all sizes and patterns, with rugged, stainless-steel construction and design features that follow high sanitation standards. This solution eliminates effort typically used to portion and fill containers by hand, allowing you to reduce labor and risk, and improve productivity and food safety.

After loading the product, a SEALER will close the package. This equipment takes a pre-made rigid container and seals the container using paper, plastic lid stock, foil, or other material. There are various sealing processes, which the sealer can be customized to perform.

When sealing highly perishable items like meat, modified atmosphere packaging, or MAP, may be employed. MAP reduces the amount of oxygen, replacing it with other gases that increase shelf-life, decrease spoilage, and retain fresh colors to entice the consumer. Also popular are skin packs, which extend shelf life without using MAP by forming plastic around the product via heat seal and vacuum. Produce and fruit will usually employ an atmospheric seal—a simple seal over the top of the package—without using MAP. This method runs faster than other sealing alternatives.

Seen here is the stainless-steel ReeMaster Series Tray Sealers by Ossid. It provides a robust and affordable solution designed for sealing trays, cups, and rounds with quick tooling changeover. This video shows the machine using a vacuum skin pack application for trays of raw chicken.

For a single machine that handles both product loading and sealing, an INTEGRATED DENEST/FILL/SEAL MACHINE will separate pre-made containers and drop them as individual units onto a conveying device, filling the containers and then sealing them in a single, continuous operation. Denesters can be loaded horizontally or vertically and come in various styles. Screw denesters work well for cups and bowls, while trays may be better suited to pick and slide denesters or peel denesters. Pick and place denesters work well for all three packaging types.

Serac’s LINEA XS is an example of an integrated denest/fill/seal machine, with up to 5 different products filled simultaneously, high-quality heat-sealing, and a modular design allowing for easy machine upgrades.

For more videos on packaging machinery and materials, please subscribe to our full 201 series. Looking for a searchable directory of more than 900 packaging and processing suppliers? Visit ProSource.com to search suppliers by package type, material, or features. Plus, we want to hear from you. Comment below what you thought of the video or if there are other packaging types or machinery and materials you’d like us to cover. Thanks for watching!