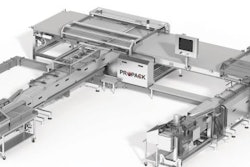

Bags will be discharged randomly from both a primary and secondary bagger onto two 90 degree curve incline conveyors, built at different elevations, that ultimately merge onto a single conveyor line.

Three servo driven metering belt conveyors were placed prior to the merge. The bags detected on the top conveyor are "injected" into the gaps on the bottom conveyor with assistance of vacuum metered belting prior to the merge.

Individual baggers deposit on both lines at predetermined speeds providing minimum gaps between product in order to complete the vertical merge.

The bag merge gap is incorporates standalone electrical controls, servos, sensing logic, VFD's, Rockwell Automation Panelview Plus, Allen-Bradley processor and two remote e-stops. Bags may occasionally contact each other but will exit the combined conveyor with no gap.