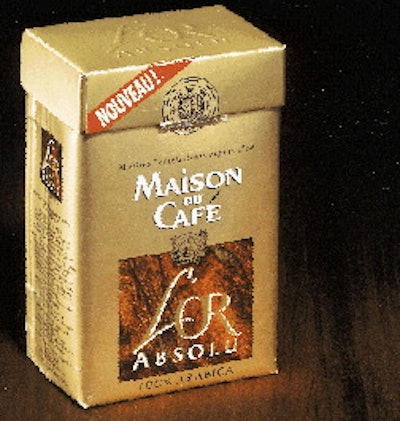

Said to be number two in the French retail market, coffee producer Douwe Egberts France S.A. sees itself as an innovator in the industry. Its 11 product offerings under the Maison Du Café name include a broad range of flavors sold at varying prices, and they're available in formats ranging from typical brick packs to elaborate gift sets. Over three years ago, the LeBlanc, Mesnil, France, subsidiary of Chicago-based Sara Lee began work on a new type of package with Goglio Luigi Milano S.p.A. (Milan, Italy). Called the Conor System, it's an integrated grinding/packaging concept whose chief advantage is that it recovers essential aromas typically lost in other forms of coffee packaging. In March, Douwe Egberts became the first in the world to commercialize the Conor System when it launched its L'Or Absolu line in a 250-g (8.825-oz) pack. The new paper/foil, brick-shaped package is designed as an alternative to the vacuum-packed brick that is popular for coffee in Europe. At 27 g, it weighs 2.5 times more than a vacuum brick, but it's still 3.5 times lighter than a metal can. Douwe Egberts president Pascal Jouannet chooses not to reveal the premium paid for the new package, though he admits it is more expensive than a vacuum-packed brick. Suggested retail price for the 250-g pack is the equivalent of about $3.00, a slight premium over comparable brands. The advantages of the new package include an easy-peel foil lid beneath a hinged friction-fit overlid; that means no scissors are needed for opening. Internal frames add form and rigidity, as well as stacking strength, creating a free-standing package. Its tight cube, says Goglio, occupies minimal inventory and shelf space. It can be decorated with superb graphics, too, and though the hinged lid doesn't provide a hermetic seal when the container is reclosed in the home, it's airtight enough to obviate any need to empty the coffee into another storage vessel. At the retail level, Douwe Egberts is hoping that the unique-ly shaped, colorful container is enough to cause consumers to pick it up off the shelf. Once in their hands, the company hopes the texture of the package-very different from typical brick packs and bags-will interest them enough to bring it home. In French households, says Jouannet, the package is one of the first for coffee to offer reclosability. Expected shelf life of the unopened pack is one year. However, he says, "the average pack of coffee in a French home lasts about one month, so it's really not an issue." Unconventional product handling The best way to grasp the significance of the Conor System is to compare it with conventional methods of grinding and packaging coffee. In a typical canning operation, after the coffee beans are roasted and ground, the product is taken to degassing silos. Here the CO2 that roasted coffee naturally gives off has a chance to dissipate. Without this step, the CO2 would build up inside the can and possibly cause a bulge or even burst a seam. Unfortunately, the degassing period also allows valuable aromas to dissipate as well, diminishing flavor and freshness. Another alternative is to use a foil-based flexible film lamination and a one-way degassing valve. In this arrangement, the coffee can be packaged shortly after roasting and grinding because the CO2 has a chance to escape the package through the valve. And because it's a one-way valve, no oxygen can get in to attack the coffee's freshness. Although an improvement in protecting the freshness of the coffee compared to degassing and canning, this method still provides ample opportunity for precious aromas to be lost between the grinding process and packaging. Recovering aroma The Conor System aims to address the aroma-loss issue by integrating grinding and packaging. Grinding is done in a chamber free of oxygen. Also important, during the grinding process, the coffee is exposed to liquid nitrogen, a cryogen that ensures the coffee is not overheated. In this enclosed, cryogenic environment, the beans are kept in the 15 to 20°C (59 to 68°F) range, considerably cooler than comparable grinding environments. This cryogenic environment prevents the dissipation of the coffee's aromas, keeping them locked up in the ground beans, says Goglio. Another crucial piece of the Conor System is the specialized piping that carries to the package the mixture of gases, given off during grinding, in which coffee aromas have been entrapped. These are piped directly to the package, which sits beneath an aroma retention hood at the filling station, rather than being allowed to escape. As the aroma-laden gas mixture enters the container, it displaces residual O2. "The nitrogen carries the aromas and flushes the air out so when the coffee is filled, the original aromas and nitrogen are in," explains Dr. Tullio Vigano, CEO of Goglio's American counterpart, Fres-Co System USA (Telford, PA). Form/fill/seal packaging As for the packaging part of the operation, it's a modified form/fill/seal operation. The package is formed and filled on its side, then turned upright for final closing. Neither Goglio nor Douwe Egberts will discuss particulars about gas flushing and aroma recovery. The package is formed from rollstock whose graphics are gravure-printed in six colors. Its structure, outside-in, consists of 80 g/m2 paper/19 g/m2 polyester/19 g/m2 aluminum/70 g/m2 polyethylene. This material is wrapped around a rectangular mandrel. An internal frame, 2.5 mm thick and made of high-density polyethylene, is inserted at what will be the top of the package to keep the square shape. At the opposite end, a paperboard base made of a PE-coated 460 g/m2 stock is heat-sealed in place to form the bottom. This package is transferred to the filling station where coffee is dispensed. Then an aluminum/PE flexible lidding material, housing a one-way degassing valve from Fres-Co, is heat-sealed in place. Filled and sealed, the package next has a paperboard flip-top lid glued in place. A leaflet containing reclosing instructions and product information is inserted prior to closing. A tamper-evident seal is applied after closing. Douwe Egberts is operating the complex line at speeds of 40 packages/minute. But those speeds didn't come without considerable tweaking. Says Jouannet, "You have to place the top frame and seal very precisely, so it took a lot of fine tuning to make it work correctly." Yet the Conor System has been successful enough to warrant purchase of a second machine. "We've already incorporated improvements in the second machine," says Jouannet. "We've ordered a third machine and that will work even better than the second and the first. We're still in the learning curve, but it delivers a nice package."