Open Core Engineering allows OEMs to access the control core of the Rexroth IndraMotion MLC and IndraLogic XLC controller systems from applications based on high-level languages.

Open Core brings the requirements from previously separated engineering worlds together in one integrated solution. Software tools and function toolkits build entirely on open standards and technologies. The new Open Core Interface enhances the software engineering – which until now has been focused on PLC automation – enabling it to work with applications based on high-level languages. With numerous function libraries, which are adapted to different development environments, it is now possible to have functions directly access the control core.

This allows OEMs to realize customized software functions in-house and to integrate IT technologies based on high-level languages into their automation solutions.

Specific examples are the integration of simulation tools or the use of smart devices with native apps. The Open Core Interface makes it possible to integrate production machine functions and data out of IT-based applications such as management execution systems.

With the Open Core Interface, OEMs are free to choose their platform – PC, controller, or smart device. They can also choose the required programming language: from C/C++, C# (.NET), Visual Basic, VBA (Office), LabView G, Objective-C, and Java, to all programming applications that support the integration of Microsoft COM libraries. They can even customize control functions for real-time applications independently of the control program. This means that the engineers can use high-level languages to write their own software functions, which then run as low-level real-time application directly on the control, or in non-real-time on external devices such as PCs or smart devices.

Now machinery manufacturers can realize innovative functions themselves - even those that require enhanced core access. This will also allow them to protect their know-how.

The Open Core Interface supports Apple iOS and Google Android. With the Open Core Interface, OEMs can develop application programs with Java as native apps, integrate smartphones seamlessly into the automation process, and support machine operators with new diagnostic and operating concepts. The native applications run entirely on a smartphone or tablet, so that the machine program remains untouched.

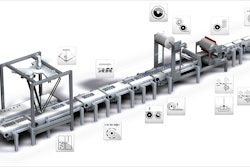

Open Core Engineering combines these new degrees of freedom in software engineering with engineering efficiency from project planning to ongoing operations. The IndraWorks software integrates all tools as well as Rexroth's industry and technology-specific know-how in the form of function toolkits in an integrated engineering framework.

The GAT (Generic Application Template) software toolkit, for instance, automatically generates the executable machine program based on the developer's instructions, thereby laying the foundation for the development of modular machine software. Another example is the FlexProfile software toolkit. It simplifies the execution of complex machine functions by automatically adjusting all drive movements to changed parameters in the production process.

A variety of industry and technology-specific software toolkits speed up the engineering as OEMs receive already pre-made basic functions. Based on open standards such as sercos, OPC-UA or PLCopen, Open Core Engineering also provides certainty for the future and protects the investments of machinery manufacturers and operators.