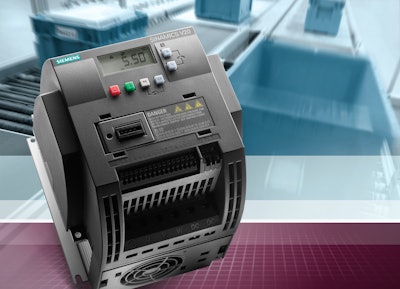

This compact drive can be connected directly in-line and mounted as a push-through installation in addition to the conventional wall-mounting method. Since no further modules or add-on options are required for operation, the installation time is minimized. Additionally, the integrated Basic Operator Panel (BOP) enables trouble-free on-site commissioning and operation. Besides the universal serial interfaces that allow for easy connection to Simatic PLC controllers, a Modbus interface is also included for communication with third-party controls. Pre-built connection and application macros are used for facilitating application-specific settings. For units with power ratings higher than 10hp, a braking resistor can be connected directly to integrated braking chopper.

Operation of the new Sinamics V20 drive is as easy as its commissioning. Parameters that have been optimized for one application can easily be transferred to other units using SD or MMC cards via the BOP interface or the battery-operated Parameter Loader — even without powering up the drive. The current firmware can be easily loaded as well.

Tailored inter-connectivity and application macros (i.e., for pumps, fans and compressors) provide the correct settings for the particular application. The Keep Running Mode automatically adapts the Sinamics V20 drive to the power supply to achieve higher availability when operated on unstable networks.

Enhanced cooling concept and coated PCBs and electronic components, halep make the Sinamics V20 extremely rugged, both electrically and mechanically, making the unit reliable even in harsh environments.

The demand-driven regulation of the motor speed also provides increased energy savings even for basic applications. The Sinamics V20 is equipped with an energy-optimized control mode (ECO-mode) for increased energy efficiency. ECO-mode automatically adapts the magnetic flux in the motor to the optimum operating point. In addition, the DC link coupling enables efficient energy utilization of drives grouped together. Further, the Sinamics V20 can be set to hibernation mode, which prolongs the service life of the motor and also reduces system component wear (i.e. pumps). Additionally, by displaying real-time energy consumption on the operator panel display, the operator always has the drive’s energy and cost efficiencies in focus at all times.