A brand leader in the design and manufacturing of processing and packaging machines for the pharmaceutical, cosmetics, and food industries, Italy’s MG2 has faced the same challenges that other OEMs have faced as the ongoing pandemic has severely limited the movement of both people and goods.

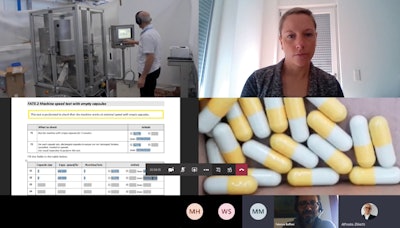

But the firm has overcome some of these difficulties thanks to remote working solutions like Microsoft Teams, video conferencing, and Office 365. In fact, by relying on this technology, MG2 successfully carried out a Factory Acceptance Test with Dr. Gustav Klein GmbH & Co. KG, a specialist in contract manufacturing and distributing herbal medicinal and homeopathic products.

The machine at the center of the remote FAT is a compact capsule filler with a maximum speed of 48,000 capsules/hr. It’s equipped with two dosing units for powders and pellets, two capsule transport size parts, and a statistical weight control system Model SWC. Dr. Gustav Klein bought the capsule filler knowing the COVID-19 pandemic was underway. That’s why a remote procedure had to be defined to both run the FAT and carry out product validation.

“In this first remote FAT we used two video cameras,” says Eng. Fabrizio Buffoni, MG2 Area Manager, “one fixed and one on the operator. Wearable technology allowed us to show all the components purchased by the customer. The live procedure totally corresponds to the Factory Acceptance protocol that we usually apply. It makes it possible, in fact, to verify full compliance with the order and that the machine operates correctly.

“In this specific case, the customer asked to weigh some of his capsules once a production batch was finished. The capsules were then collected in three stages during one hour of production: at the beginning, at the end, and in the middle of the batch production. They were weighed one by one, subsequently emptied, and weighed again. The goal was to give the customer evidence that the capsules had been filled as expected.”

The remote procedure, which covers all the steps necessary for the correct execution of a FAT, involves sharing all the documents of both validation and order confirmation, strictly following what is displayed by the two cameras. The batch reports processed by the machine were made available to the customer in real time, thus overcoming the limits imposed by the physical distance between machine builder and machine buyer. The test recording, lasting three working days of eight hours each, is another tool that let the customer objectively evaluate the test.

“A key element of the FAT is the objective evaluation of the correct capsule filling,” says Buffoni. “In this particular case, the evaluation was highlighted by two specific tests: the SWC weight control system, which tests a capsule every 20 seconds, and a further statistics check requested by the customer. Specifically, we manually weighed the capsules on a scale in front of the camera, thus ensuring maximum reliability and objectivity of the filling process.”

In addition, by relying on the same remote technology, it was possible to verify machine documentation items such as the user manual by connecting the customer with the MG2 specialist in charge.