Myth #1: There are no set standards for RFID today.

Truth:The fact is that there are several RFID standards today. EPCglobal is helping to define the standards for the next generation technology, but the big players--Wal-Mart, Department of Defense (DoD), and select Fortune 500 companies--are aggressively moving forward with RFID, and many have already implemented current-generation EPC technology. Smaller businesses will likely take their cue from the industry leaders as RFID standards continue to evolve, emerge, and ultimately become entrenched.

Myth #2: Replacing bar code-based processes with RFID processes will achieve return-on-investment.

Truth: Feeling the pressure, some companies will implement RFID technology into their manufacturing and logistics operations for technology’s sake. That does not guarantee a fast-path to ROI. In order to impact the bottom line, implementing RFID must be linked to a definitive business goal. For most companies, it’s cost prohibitive to convert to RFID on a broad scale or doesn’t even make sense. Achieving greater ROI with RFID is not time sensitive; it is application dependent.

Myth #3: RFID benefits only retailers, not packagers.

Truth: While RFID has clearly highlighted major retailers (Wal-Mart, Target, Albertson’s), several Fortune 500 consumer packaged goods companies including Procter & Gamble and Gillette are blazing an RFID trail across their supply chain. Packagers might not achieve incremental ROI, but there are benefits to be gained. They should view RFID compliance as a means to capture more detailed inventory information, increase visibility throughout the supply chain, and reduce complaints. More satisfied customers and increased store in stocks lead to more business.

Myth #4: RFID is the only way to automate manual warehouse receiving processes.

Truth: In certain cases RFID may be appropriate for warehouse automation, but it is not the only solution. In fact, one of the biggest paybacks of evaluating potential RFID uses in the warehouse is that this investigation helps uncover big savings opportunities that don’t require RFID. Tagging of cases can be done with bar-code technology and still yield tangible ROI by eliminating the potential for manual intervention and error.

Myth #5: The EPC is an RFID replacement of current bar codes.

Truth: Electronic Product Code (EPC) used in RFID tags and bar coding are complementary data-capture technologies. Even with large-scale adoption of RFID, there will be a continued need for bar coding to coexist with RFID into the foreseeable future.

Myth #6: Adoption of RFID won’t require facility, equipment, and process changes.

Truth: Incorporation of RFID will necessitate a new look at existing business processes. As requirements and technological evolutions arise, companies will have to revisit their standard practices if they expect to gain new efficiencies from RFID. They will need to ensure that there is a high level of compatibility in the integration of RFID within the facility--how the physical layout is organized, how labor is deployed, and even how the equipment itself is constructed. The good news is that this level of change can prompt even better practices that otherwise would not have occurred.

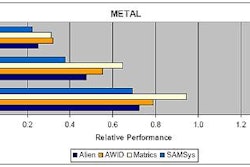

Myth #7: Readability challenges are only for metal and liquid products.

Truth: There’s no substitute for testing RFID with your own products in your own environment. You need to make sure that you get a consistent, reliable read rate that meets your specific needs. Experiment up front to thoroughly test these applications before making a large investment in an RFID solution.

Myth #8: Consistently reading every EPC on a pallet is easy.

Truth: Although using EPC tags beats scanning, it is not foolproof. So many variables can interfere with accurate and reliable read rates. These might include the sizes of boxes, the number of cases, travel speed, types of tags, tag placement, reader/antenna placement, and even the product mix itself.

Myth #9: All RFID tags are the same.

Truth: No so, there are different types of tags for different applications, depending on the environment and business processes where RFID will be applied. Use the following checklist to determine which types of RFID tags are most compatible with your unique business environment:

Don’t be fooled by the existing hype about RFID, your unique business environment will dictate your RFID requirements. Remember that RFID doesn’t have to be an “all or nothing” proposition. It can be implemented in phases and applied to specific projects to accurately gauge ROI benefits. Even as you learn from the examples of others, now is the time to research the possibilities, understand the challenges before you, and earmark funds for forthcoming RFID hardware and software investments.

--RL