If one of these threats actually unfolds, it could devastate a company.

So how does a food company manage risk?

First, you need to review the basic components of risk, beyond process

control and quality assurance. The basics of Risk Analysis are:

• Risk Assessment—including the sub-routine of hazard analysis

• Risk Management—risk mitigation, risk transfer, or risk acceptance

(for example, HACCP, GMP, FMEA, etc.)

• Risk Communication—including an ongoing review

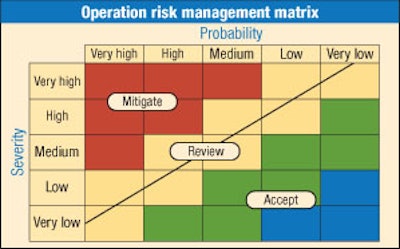

Usually missed in the analysis is getting corporate finance to put an

actual dollar figure on what a threat will cost if it actually unfolds

and becomes something the corporation must deal with. Reality may be

that your business could be in the “accept” area not needing to do

anything (see chart). Lower-probability emerging risks are commonly

ignored, as corporate finance essentially says, “How could that be a

risk when I don’t see any mortalities?”Still, the packaging

professional is the one held responsible for ensuring there won’t be

any mortalities.

Second, you need to apply risk concepts to everyday practice in

packaging. However, small data sets make it hard to create the rigorous

ROI-based financial analysis that CFOs are used to seeing. Groups such

as the Food Safety Alliance for Packaging (FSAP) and the Society for

Risk Analysis (SRA) are working to help apply tried-and-true methods to

emerging risks in new areas such as packaging. For example, FSAP has

developed a Packaging HACCP program, and the SRA is constantly adapting

risk theory to met the needs of real people in real jobs.

Third, once you do figure how to apply the risk concepts, be very aware

of the hazard analysis (HA) sub-routine in risk assessment. The HA step

in HACCP is so critical.

Finally, on the Probability versus Severity Matrix shown here, where

would you put product counterfeiting? Would you enter a summary or

specific type of counterfeiting? How does your company define the line

between “mitigate” and “accept?” Do your CFO or Chief Risk Officer have

a chart like this?

Be aware that senior management is now using enterprise risk management

and charts such as this to forecast risk. By focusing on the HA step

and using tools such as this matrix, you can improve management of the

risks that could destroy your company. Enterprise Risk Management is

coming—are you ready?

At Michigan State U., John Spink ([email protected]), MS, CPP, is an

adjunct faculty instructor and the director of the Packaging for Food

and Product Protection (P-FAPP) initiative within MSU’s National Food

Safety and Toxicology Center.