Product manufacturers want to put the appropriate product in the right consumer’s hands while also reducing costs and sacrificing as little inventory as possible to obsolescence. Contract packagers want to save on time and materials, too, but also develop competencies in new areas and free up precious warehouse space.

An emerging factory-floor model called Last Moment of Differentiation (LMD) might meet all of these needs when used under the right conditions, and it is gaining traction in contract packaging. And co-packers say product manufacturers might gain additional bonuses: the potential to reduce time to shelf and expand packaging’s sales potential—it’s really a win-win all around—while also saving as much as 70% of the costs associated with packaging, its supporters say.

LMD delays package printing until just before or after the product is filled, or the package is assembled. By holding off on customizing the label text and logo until just before shipping, the technique holds substantial potential to slash packaging, inventory, and logistics costs, say its proponents. It gives consumer packaged goods (CPG) companies the capability to differentiate products, via tactics such as labeling, on an as-needed basis. They also can order differentiated products in the quantities they need, as they need them. By scheduling printing at the end of production, CPG companies significantly reduce the likelihood for mislabeling their products and lessen the risk of making them obsolete.

Applications in CP

The LMD model might be particularly well-suited for contract packaging because it offers a bridge to two opposing forces in the future of packaging: Products are continuing to proliferate as consumer markets expand, and the growth demands that packaging processes simplify complexity.

Beverage bottles provide a useful illustration for how LMD can work. Suppose a beverage company wants to be ready to produce commemorative packages for its carbonated-beverage brand should the local high school football team win the state championship. The beverage company plans to use the same bottle mold, cap, and label as for the brand’s everyday packaging.

Tens of thousands of unlabeled, filled beverage bottles arrive sealed, along with blank labels, at the co-packer’s warehouse facility. The local team is victorious, and the beverage company instructs that the next production run also include 1,000 specially marked bottles. The co-packer moves the bottles into production, printing and affixing the special-order labels to 1,000 bottles, and adheres the brand’s everyday labels to bottles for the rest of the production run. If the beverage company needs more commemorative packages, the co-packer can print and adhere the special labels to additional bottles as needed.

This example illustrates how LMD enables product manufacturers to hold yet-to-be-assembled-and-labeled products on their co-packer’s premises. They can request that these products be assembled, packaged, and labeled in a particular manner, and then immediately shipped either to a distribution center or directly to stores. The only packaging component to swap out is the labels. The product is the same, and the other components are common to every one of the beverage company’s bottles that move down the production line, so the labels can be changed at the last minute.

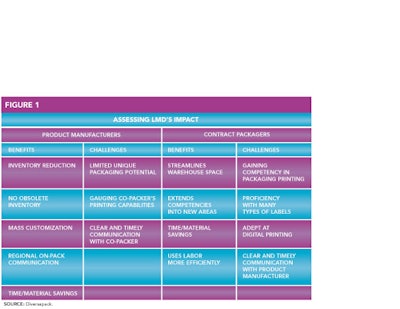

On page 17, Figure 1 lists the benefits and challenges associated with LMD. Figure 2 details the linear steps of the current production process and shows the steps that would be eliminated by using LMD.

“The conventional process of creating a private-label or branded product is that the product comes into the contract packager in many different parts, and you put it together,” says Ron Pontolilo, vice president at Jacobson Companies (www.jacobsonco.com), whose co-packing division is working to adopt the LMD model. “It’s very labor-intensive, and it only allows that CPG company to create one product at a time.”

“But now you can bring in a big box of, let’s say, generic cups, and they could sit there,” Pontolilo says. “Then the CPG company would tell you day-to-day how much to box and what the box would look like, with labeling, and you’d immediately print, package, and ship it.”

Such flexibility enables the beverage company with the commemorative soft-drink labels to order only what is needed, when it is needed. That contrasts with traditional production methods that might produce too many of the custom packages in a single production run based on estimating how many units will be needed. Producing too many custom packages potentially creates waste for both the product manufacturer, which now has obsolete inventory, and the co-packer, which has committed unnecessary packaging-line time and labor.

Using LMD, generic items can be packaged and printed in many ways and shipped immediately. Product manufacturers can avoid the expense of paying co-packers to repackage items that didn’t sell or were ordered in excessive quantity in one packaging form, by arranging them in another configuration in another package form for retail sale.

However, one challenge that LMD presents for co-packers is that when label completion is delayed, the co-packer becomes responsible for printing in addition to packaging. So any co-packer that wants to be successful with LMD will need to become proficient at printing. Printing is a competency that product manufacturers should assess as they qualify co-packers, if they believe that LMD could meet their future packaging needs.

Contract packager Diversapack LLC (www.diversapack.com) began exploring the LMD concept more than three years ago. It has begun taking the first steps toward execution, says Thomas Vogt, vice president of sales.

“You’re trying to be instantaneous in your packaging response,” Vogt says. “One of the ways of doing this is having a decoration method that is the last thing you do and that can offer variability at no additional cost.”

Gauging LMD’s impact

The advantages and cost savings associated with LMD come in a number of ways. They are detailed below and listed in Figure 1.

Inventory reduction. Because the LMD scenario requires the co-packer to warehouse goods and direct-ship finished products, the cost of housing already produced inventory can be reduced for product manufacturers, says Diana Twede, professor in the Michigan State University School of Packaging. She is an expert on a similar packaging method—postponement.

“If you wait until the last minute, you reduce the risk of labeling the product in the wrong way,” Twede says. “You don’t wind up with obsolete inventory.”

For example, if the co-packer maintained an inventory of detergent bottles with no decoration, they could be filled with any version of the detergent that the product manufacturer requests, as long as the products use the same bottle mold.

“If you could fill it at the end of the line and apply the right label on the bottle, you may have increased your cash flow,” Vogt explains. “You have less inventory expenses and you can meet the CPG company’s request in 48 hours.”

Differentiation. By introducing last-moment printing into the package-production equation, individual product units can be differentiated from each other at the point when the product is packaged, says Jeff Topits, director of technology and engineering at Diversapack. Rather than having individually printed and decorated bottles, the custom labels would be affixed at the end of the line.

A section of the label or a pouch can be left blank for a special last-moment message, Twede says.

Product manufacturers and retailers can call on LMD to provide a custom label as a tie-in to a promotion or coupon offer, says Francene Lord, national accounts manager for Diversapack.

This capability heightens the marketing impact of packaging by providing regional appeal for consumers, Twede adds. “I think this is a really important area for contract packagers because they can play locally,” she concludes.

Scheduling. Product manufacturers can request new production schedules for a custom-branded or -labeled product at a moment’s notice, even if that product hadn’t been in place in the production queue before, Jacobson Companies’ Pontolilo says. Even more intriguing, he adds, is that LMD lends itself well to catalog retailers or consumer product companies that provide an assortment of goods.

Using this production model, product manufacturers can call for goods from the co-packer on a per-order basis. A catalog order could be placed through the retailer and then sent directly to a co-packer for picking and packing, for example.

What the future holds

Printing directly on the product is the Holy Grail for LMD. Here, savings can rack up further and faster, Vogt says.

“Once you’ve made your design and everyone agrees to it, you go right from design to ready to decorate the container,” he says. “There’s no transportation of raw materials to the printing site, no preprinting process taking place, no shipment of labels to manufacturing, no storage or inventory of labels.”

Digital printing capabilities are moving quickly in that direction, Twede says. Even without the capability to print directly on the product, high-quality labels are available today that can be printed digitally at a moment’s notice.

“The benefits are you get more opportunity to postpone,” Twede says. “The quality is good and the cost can be low. Especially for contract packaging, that would be of great advantage. They just have to get artwork and could immediately put it on the label.”

Of course, co-packers will need flexible production capabilities, too, Pontolilo adds.

“You have to have the high speed and efficient equipment in place to do this,” he cautions. “You can’t have a break down in this equipment because today we’re making this into ABC and tomorrow into XYZ and printing it in a different manner.” But, he says, expect to see LMD make inroads in packaging and production methods in the near future.

“I’d say it’s in its inception stage,” Pontolilo says. “I have to believe in this world, it’s going to go.”