This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

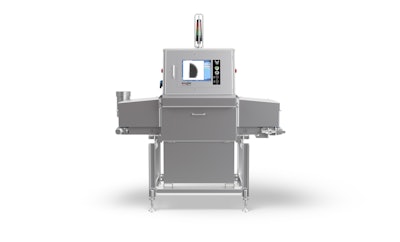

Manufacturers operating in harsh washdown environments face unique challenges, not only in maintaining food safety and operational efficiency, but also in meeting the growing demands of regulatory audits. Engineered for these environments, the Eagle Pack 400 HC with PXT™ offers dual energy technology, superior contaminant detection, and inline quality checks—all in a hygienic, easy-to-clean system that helps processors stay audit ready.

Ideal for meat, poultry, seafood, and dairy processors, the Pack 400 HC is hygienically constructed to NAMI standards and meets IP69 ingress protection specifications. It features interlocked hinged louvers, tool-free belt removal, and a design that allows one person to fully disassemble the machine in minutes, supporting faster sanitation and reduced labor.

At the core of the system is Eagle’s newly advanced PXT™ detector, which uses photon-counting dual energy technology to find even the smallest contaminants and bone fragments, particles often missed by conventional x-ray systems. The system is powered by the latest version of SimulTask PRO™ software, offering a greyscale range of up to 65,535 values for unmatched image clarity and data precision.

Beyond contaminant detection, the Pack 400 HC with PXT™ performs simultaneous inline product integrity checks. Processors can verify mass, count components, identify missing or broken items, and detect unwanted voids—all critical for ensuring quality and audit traceability.

Eagle will showcase the Pack 400 HC with PXT™, along with other advanced X-ray systems, at the upcoming PACK EXPO event, held Sept. 29–Oct. 2 at the Las Vegas Convention Center in Booth N-7610.