This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Spee-Dee’s Test Lab replicates a customer’s plant conditions to run products like they would in-house. This allows Spee-Dee's technicians to simulate an actual product run and confirm that customers will achieve their desired rate, accuracy and line efficiency.

The lab is run by Dennis Mulder, Applications Technical Expert, who has been with Spee-Dee since 1981 and has over four decades of application knowledge and product expertise. Mulder and his team coordinate every aspect of the testing process and work to ensure that efficiencies are maximized for a customer’s application. Customers are encouraged to visit the lab to see their product run on Spee-Dee equipment.

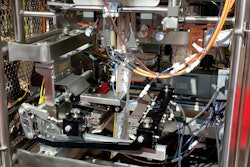

A key feature of the addition is a new 15 ft x 40 ft mezzanine, with a total of five test bays. Three test bays have cutouts for integration with ancillary packaging equipment such as vf/f/s baggers. Product is fed from above using feed screws, a small vibratory feeder and/or a vacuum conveyor. With three available styles of mobile test equipment, multiple augers, cup fillers and a rotary test turret, the lab is equipped to run tests for various applications. The lab allows for the setup of a rotary filler with a test loop to test rigid container applications.

Bulk product samples will be stored on a new racking system in the lab, which provides expanded storage.

The updated space has full washdown capabilities for easy clean-up, which includes two sinks, an automatic washing machine and an instant hot water heater. Exterior hot and cold outlets are present for using hoses to wash in each bay. The wash area and mezzanine both have water drains to ensure sanitary operations.

A density meter device and a Powder Flow Test unit allow Spee-Dee to collect critical data on all products, which improves the tooling specification process on even the most difficult of products.

“The expansion of our test center is an essential component to providing our customers with excellent service, as well as continuing to expand our offerings,” said Dave Navin, Spee-Dee's President & CEO. “The ability to run tests similar to our customers’ plant conditions will allow us to provide exceptional service before their machinery even leaves Spee-Dee.”