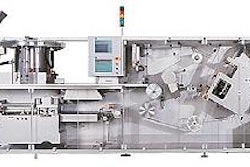

It features operation at speeds of up to 50 bottles per minute using round, square, triangular or irregular bottles. This Monoblock is compact, with easy access to all stations for service or changeovers.

The fully automatic version includes bottle placing, filling, wiper placing, and cap/applicator placing and torqueing. It is PLC controlled, with "no bottle…no fill" protection, and a reject chute for bad bottles. Other filling and assembly Monoblock configurations are available from TurboFil for applications such as: nail polish, cartridge filling, perfumes, pharmaceutics, and diagnostic reagents. For more information, visit TurboFil at the upcoming EastPack show in New York in booth 4829.