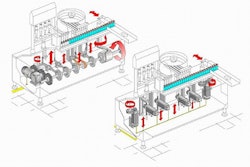

Networked communications on Unilever’s two lines are a cost-saving alternative to a standard set up of programmable logic controllers and point-to-point wiring.

“That’s one of the biggest things about these projects,” says Unilever’s Baltimore TPM manager Cal Soper. “For each filler, which is the center of the network, we saved about one-half million dollars for controls.”

Soper attributes the savings to reducing the costs of wiring and cabling otherwise associated with connecting equipment on a full production line. “With PLCs, this line would have needed seven to nine cable trays,” he points out. “And there’s no need for motor control centers. Instead, all we need is a little fuse box.”

All 18 of the mass-flow meters communicate via a Rockwell Automation (Milwaukee, WI) DeviceNet network to an off-board Allen-Bradley SLC 5/04 PLC. The operator interface is an Allen-Bradley PanelView touchscreen console that enables the operator to select a preset product recipe that the system then downloads to every flow meter. The interface allows on-the-run control or adjustment over every aspect of the filler except the washout, according to Soper. The uncasing and casing operations are also on the network.

The electronics and programming was handled by Pneumatic Scale, which reverse-engineered the meters’ original software. That reprogramming eliminated proprietary software to help speed up the overall communications.

The nature of mass-flow fillers versus conventional fillers also helped simplify the complexity of the network. Additionally, the network permits data collection, which is done for product density and for fill weight.

“The lines communicate especially well and are easy to troubleshoot when needed,” sums Soper.

See the story that goes with this sidebar: Mass flow = efficiency squared