This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Aylward Enterprises, a specialist in oral solid dose (OSD) packaging automation, announces it will exhibit at PACK EXPO Las Vegas 2025, taking place September 29 to October 1 at the Las Vegas Convention Center. At Booth N-5010, Aylward will spotlight its Cube Feed System, known for precision, flexibility, and GMP-compliant performance, alongside its new bulk product elevator, designed to enhance upstream product handling and integration.

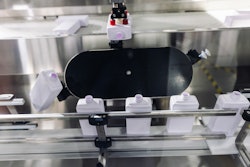

The Cube Feed System from Aylward from Aylward provides unmatched flexibility for high-speed blister feeding, delivering accurate placement of tablets, capsules, and softgels into preformed cavities. Its modular design allows rapid changeover and integration with nearly any blister machine, while minimizing cross-contamination and maximizing uptime. Ideal for GMP-compliant lines, the Cube Feed is a proven solution for manufacturers seeking precision, consistency, and low-maintenance operation in feeder technology.

Aylward’s new Bulk Product Elevator is designed to safely maintain product levels at rates of up to 1 million units per hour. Engineered for simple integration with virtually any type of packaging equipment, the elevator features tool-less changeovers and an easy-to-clean design, helping manufacturers streamline upstream product delivery to the Cube Feed while preserving product integrity and minimizing downtime. The improved design also allows the complete elevator structure to be lowered to a height that enables it to pass through a standard personnel doorway within the production area. This makes it easy to move the elevator between packing suites or out for cleaning, allowing a clean elevator to be swapped in for even faster product changeover. By enabling movement through standard doorways, the elevator eliminates the need for specialized infrastructure or disassembly, simplifying sanitation procedures and equipment rotation across packaging zones.

While the Cube Feed and new elevator will be featured live at the show, attendees can also view video demonstrations of Aylward’s full equipment portfolio, including the EPI-3015 PDA blister machine and WKH-100 cartoner from ELMACH. These systems continue to play a key role in Aylward’s integrated packaging solutions for pharmaceutical, nutraceutical, and healthcare manufacturers. Together, these technologies offer a scalable, space-conscious solution suite for manufacturers focused on flexibility, uptime, and operational efficiency, particularly in environments where frequent clean-in-place procedures or equipment rotation is critical to maintaining compliance.

To explore the Cube Feed System and new Bulk Product Elevator, visit Aylward at Booth N-5010 during PACK EXPO Las Vegas.