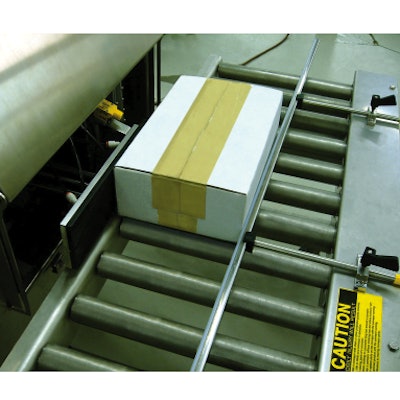

Unit features a simple head-on stand that offers the flexibility to apply different types of pressure-sensitive labels to the side, top, bottom or corner of virtually any-shaped product. Even though all key components are encased, they are easy to access, keeping downtime to a minimum when changing labels or the printhead. Because wiring is also encased, there is much less chance for shocks, which is a major concern when the unit is deployed in high-moisture environments. The 1-ft. x 1-ft. access panel is configured for easy access when changing out labels and the printhead. Heavy-duty rods and cylinders handle up to 60- to 70-lb. boxes of product. The compact design and small footprint make it easy to set up at any spot on a production line, and the entire machine is on wheels and features a self-contained four-foot section of conveyor for easy staging of product to the printer and label applicator. The plug-and-play design adjusts to match existing conveyors, and the printer/label applicator and the conveyor all move in sequence.