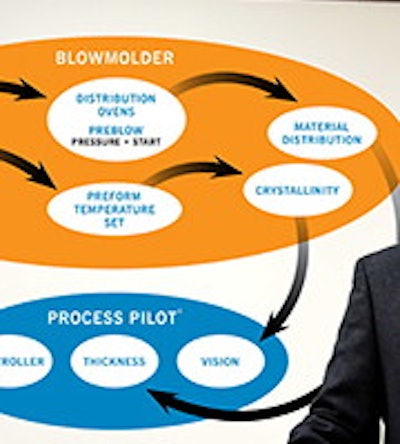

Crystallinity management is monitored in the same way container material distribution is managed and maintained: by managing preform energy distribution during the heating process, The Process Pilot system works in conjunction with the reheat stretch blowmolder to continuously monitor every bottle to detect small changes in crystallinity while actively maintaining desired crystallinity levels. At the same time, the system eliminates the occurrence of haze and pearlescence.

The Process Pilot automated blowmolder control system can be a vital tool in the production of light weight bottles while improving overall bottle performance and quality.