This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

MPS broadened its EF multi-substrate press line which is now available in three different versions to accommodate market demand and offer a solution for unique application requirements. With different demands for press solutions ranging from cost-efficient to advanced, fully-automated machinery, and respecting changing market demands, the new EF press offering will serve all segments of the label, flexible packaging and converting markets.

The standard EF press offers an automation package including Job Memory. From this standard configuration, two additional automation packages for the ultimate in print setting control can be configured to further increase the productivity of the EF press. The following three versions of the MPS EF multi-substrate press are now available:

• EF

• EF-APC

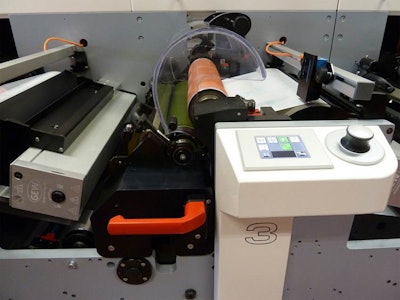

• EF-APC Advanced (shown)

Built with unique MPS innovations including iControl, Crisp.Dot, Gearless Tooling, Short Web, Multi Drive and Job Memory, the standard EF provides a lower-cost solution with considerable automation capability. Job Memory memorizes all machine settings used for a specific job and with the user-friendly iControl system the press is easily controlled by the press operator.

From the standard EF design, the EF-APC version is enhanced with automation on the print sleeve settings. With the use of servo positioning technology, the print sleeves are loaded automatically on the print unit, while the APC (Automatic Print Control) option automatically sets the desired print pressure settings. The EF-APC version is also built with slide-out ink drawers and Dynamic Print Control to guarantee flawless and consistent print quality at all press speeds.

For further automation, the EF-APC Advanced version includes the EF-APC features in addition to Automatic Print Control on the print gap (substrate related). For initial jobs, material calibration memory is uploaded and recalled for repeat jobs. Print positional settings for plate sleeves and anilox rolls can also be stored and recalled. All desired print settings are achieved within seconds and waste quota is virtually negligible.