Krones

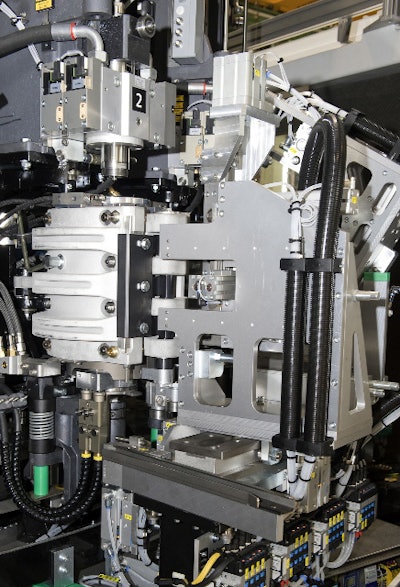

The semi-automatic system integrated into the blowing wheel shortens

the change-over time from about 3.5 minutes to less than 1 minute/blow-molding station. The different mold sets are kept securely in a

design-enhanced, human-engineered changing trolley. Unambiguous

identification of the molds using appropriately designated compartments

reduces the risk of installation errors. A rotating function principle

assures the removal position is always the same for the operator.

Companies in this product

Videos from Krones, Inc.