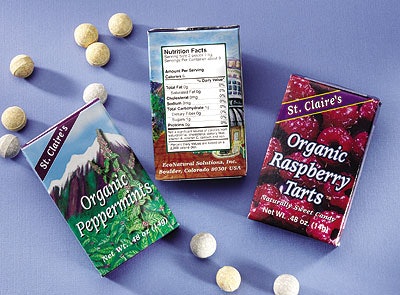

EcoNatural Solutions, a marketer of organic mints and candies, has gone from five people packing 37 cases daily to two people packing 43 cases daily thanks to an intermittent-motion vertical cartoner from Econocorp (Randolph, MA) and an automatic tablet counter from DT Industries (Leominster, MA).

Before the cartoner was installed about two years ago at the Boulder, CO, candy maker, carton erecting, filling, and sealing were all done primarily by hand. As the company grew, automation beckoned. But according to EcoNatural vice president Kris Jacobs, it was no easy task finding an automatic cartoner that was both affordable and capable of handling a small carton measuring just 2 7/16” x 1 9/16” x ¾”.

When the firm identified Econocorp’s pneumatically operated V-System cartoner as a suitable candidate, Jacobs asked other machine vendors for price comparisons. Most quoted two to three times the cost of the V-System, so it was purchased and installed. It’s rated at 25 cartons/min, and EcoNatural runs about 22/min.

Supplied by Gibraltar Packaging Group (Hastings, NE), carton blanks are 16-pt SBS printed offset in four colors plus coating. A vacuum cup pulls blanks from the magazine, erects them, and places them in a flighted track. After minor flaps and the inner major flap are folded, hot melt glue is applied to the outer major flap and it’s folded and compressed against the others.

In the next station, mint candies are released into the carton by the tablet counter. Tops are folded and glued and the carton is manually case packed. Sold nationwide, the .48-oz package of mints costs about 95¢. —PR