The new system can signal the customer when applied amounts of product are out of range, thereby assuring proper application without having to periodically weigh samples of the applied cohesive. For customers securing loads using only Lock n’ Pop without additional stretch wrap, this allows for peace of mind that the product was applied correctly and consistently without having personnel constantly supervising the operation.

The Lock n’ Pop system is durable, cost-effective and provides a virtually maintenance-free solution over other traditional pallet securing methods. The water-based cohesive is stronger than stretch wrap alone and is cold applied, making it safer than hot melt. It’s especially popular with poly bag applications like animal feed. Traditionally, bag applications are secured with stretch wrap which can weaken or topple over in transport because the poly material will force the bags to slip off each other and stretch the film to where it can no longer support the load. With Lock n’ Pop the bags are adhered to each other during stacking, eliminating any slipping or need for stretch wrap.

In warehouses where pallets are stacked high on shelves, safety is a top concern. Customers were eager to have greater assurance the cohesive was being applied and at the quantity desired and have the ability to regulate flow, range and amount.

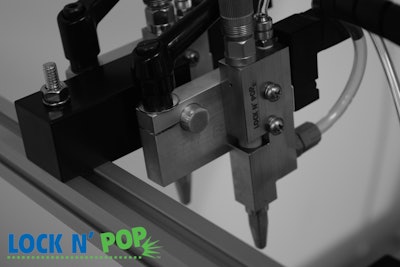

The new applicator comes with PLC control that provides customers the ability to regulate and track cohesive flowrate, range and amount. The unit can set off an alarm or integrate with the plant as required, should flow rate be off. A history log also allows technicians to access the last 1,000 logs to identify any patterns or see when the system went down. The flow sensor control can be retrofit on older U75 models. The simple retrofit can be done in 30 min. and includes replacing the control box with a larger more sophisticated version.