This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

It supports customers and adhesive manufacturers with data and analyses to optimize adhesive application quantities and brings transparency to the adhesive process. The usual safety margins in the adhesive application can be reduced or entirely omitted without risking a loss of quality in the bonding process.

AMS measures the actual adhesive consumption and compares the data with the stored reference values from the configuration database of the Robatech Control System. If the applied adhesive application quantity deviates from the defined tolerance range, a fast error message is displayed.

Fast error message in case of deviating adhesive application quantity AMS measures the actual adhesive consumption and compares the data with the stored reference values from the configuration database of the Robatech Control System. If the applied adhesive application quantity deviates from the defined tolerance range, a fast error message is displayed. The adhesive measuring system thus increases sustainability in production and creates process reliability. All measuring and configuration data is clearly displayed on the standardized user interface of the Robatech Control System and can be exported without any problems.

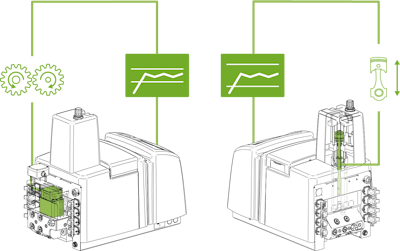

AMS is available as an option for Robatech melters of the Concept Diamond and Concept Stream line. Depending on their needs, customers can choose the cost-efficient variant with a KPC12 AMS piston pump or the more accurate and faster variant with the AMS-V measuring cell.