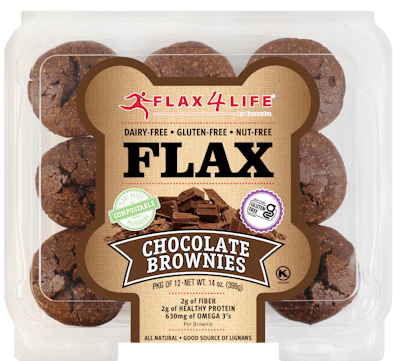

Flax4Life, a producer of certified gluten-free and allergy-friendly baked products, converted its retail muffin and brownie tray material from industry-standard PE to a new Industrial Compostable, plant-based PLA material based on renewable sugar cane. The company says this move will keep thousands of pounds of petroleum plastics from our environment each year. Plus, the process of producing these trays results in a significantly lower CO2 emission rate compared the production of PE plastics. And the only difference to the consumer is the enhanced sustainability profile where industrial composting is available.

“Our main objective is purely starting the conversation and providing resources to educate. Not every municipality has the capabilities now, but we believe by creating a demand we are increasing the chances,” says Sarah Bishop, Flax4Life Marketing Coordinator. “In the places where an industrial facility is not available, and our packaging ends up in the landfills, we are not introducing the harmful chemicals of petroleum plastics. From our research, we are creating less impactful waste on the environment.”

The material switch was not without its challenges. There was a litany of initial concerns that the package design and material ultimately overcame in the interest of sustainability.

For instance, the PLA trays required a custom mold for the air-pressed forming process to maintain relative consistency with the established product line’s existing packaging dimensions. The company chose to keep the overall dimensions and shapes the same, but modernized the look by smoothing out edges and optimizing the viewing of the product within the package.

And as is the case with any retail-ready baked product pack, shelf life was a concern.

“Luckily, the manufacture diligently tested the product before coming to market and fit our needs in relation to shelf life,” says Bishop. “Another difficulty was the amount of time it took to complete this project. From research, testing, mold-building, and dealing with [pandemic-related] supply chain issues during the last couple of months, it delayed the project by almost a year. A lot of moving pieces are involved to coordinate the change, and it was hard to align all of them.”

All of the company’s perishable baked products are shipped and stored frozen, then slacked out at store level to be displayed at room temperature. That led to concerns about how the PLA tray would hold up to the freeze and thaw process. But the PLA tray proved more than up to the task. The material is quite durable, according to Bishop. Packaging at the company’s Bellingham, Wash. facility is a manual process, but she notes that the PLA trays are quite durable and will be able to withstand any automation added down the road.

Price was yet another factor—the PLA material is currently significantly more expensive than the legacy PE—but Flax4Life saw the switch as a tradeoff that could benefit both the company itself and the planet.

“We ended up reducing our marketing and promotion budget to incorporate the cost. It was more important to us to provide better packaging,” Bishop says.

Flexo-printed labels complete the retail package unit. Various certifications, including gluten-free and Kosher, among others, are represented on the label serval times.

“We needed something visually catching and simple to understand,” Bishop says. “You only have a few seconds of the consumers attention to get your message across, and we wanted something to help identify the change easily.”

Packaging vendor good natured partnered with Flax4Life on the project and supplies the new PLA compostable trays. The brownies and muffins are available online and at retailers across the country, including Whole Foods, Kroger, Publix.