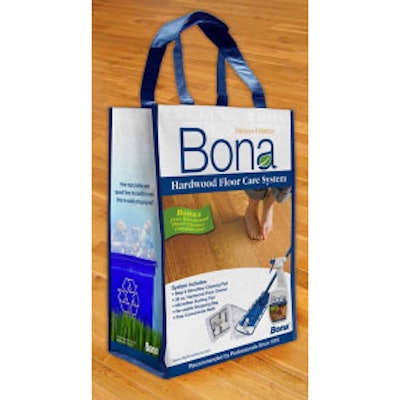

Bona US, the North American subsidiary of Bona AB in Sweden and a provider of products for hardwood floor finishing, home cleaning, and floor care, has launched its premium Hardwood Floor Care System and its Stone, Tile & Laminate Floor Care System in reusable shopping totes, eliminating the typical throwaway outer box.

The new packaging will keep 50 tons of total packaging out of landfills in 2010 alone, the company says. In addition, each reusable tote is made from recycled PET, keeping 11 plastic water bottles per bag from entering the waste stream.

Bona's guilt-free packaging provides consumers with a professional-quality, daily home cleaning solution in a progressive and reusable package. Each Bona System includes a professional, nontoxic, biodegradable cleaner; reusable and washable microfiber dry dust and cleaning pads; a four-piece Bona mop and base; and a concentrated floor cleaner refill.