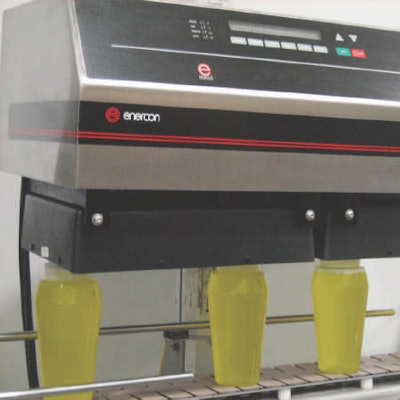

Long established as a supplier in the business-to-business market, juice manufacturer Jus-Made recently branched into the retail market with products such as coffee syrups, cocktail mixes, and dietary supplements. Such products require tamper-evident seals, so when the Dallas-based firm installed a new hot-fill line for the new products, the line included an Enercon Industries (www.enerconind.com) Super Seal Max induction sealer.

According to Tim Ray, Jus-Made's plant manager, the Enercon sealer enables the company to handle a wide range of bottle volumes and neck diameters. This is especially important because so much of Jus-Made's business in on a contract manufacturing basis. "The machine has different sealing heads available, which has allowed us to increase flexibility and the number of customers we can serve," says Ray. Jus-Made seals 63-mm cap diameters at speeds in excess of 145 bottles/min. The company also seals containers with 28-mm caps on the same line.

Cap specifics