This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

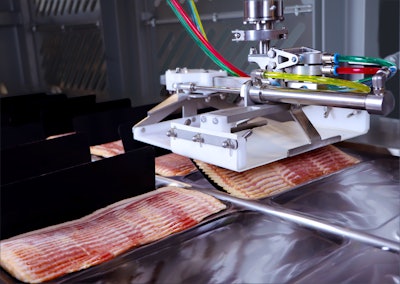

The JLS loading system has a robotic gripper end-of-arm tool that prefolds a flat bacon L-board flap utilizing a combination of linear servo actuators. The folded draft is then rotated 180 deg and articulated down into the thermoformer pocket. The Harrier bacon draft loading system features a hygienic, stainless-steel, IP69K-rated, vision-guided delta robot that has a targeting system, which accommodates a range of draft position variances on the infeed conveyor. The loading system can be integrated with other upstream and downstream equipment, such as a slicer or a robotic case packer.