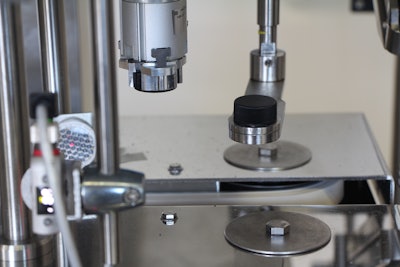

TurboFil Packaging Machines LLC, an equipment provider of liquid filling and assembly machines, introduces its servo-driven chuck capper, the Acrobat Chuck Capper, designed to offer precision torque and gentle handling without costly bottle change parts. The company says the machine is a good fit for manufacturers producing multiple SKUs.

The capper’s technology and parallel belts are used to reduce the expense of making and storing change parts for most bottles. The Acrobat’s servo motor operation should provide accurate, repeatable torque control and, for difficult threads, also perform counterclockwise thread seating.

The module’s two-chuck system features a “chasing chuck” designed to automatically locate the next bottle along the belt. This mobile, adjustable chasing chuck should allow the belt to serve as a spacing tool to replace change parts.

Positive placement and cap-specific stainless steel serrated pneumatic chucks are meant for gentle handling and minimal erosion between the chuck and the cap ridges to mitigate the risk of generating particulates that can contaminate the machine surfaces as well as bottle contents. (For smooth caps, the company also has urethane-lined chucks available.)

The machine’s touchscreen, recipe-driven HMI can validate and store torque settings, and provide easier electronic changeover of cap placement, torque parameters, cap orientation and bottle height, and other settings and options. The only factor that should require mechanical adjustment, which is performed via scaled turn-wheel, is belt gap.

The unit is designed to:

- Handle a variety of caps up to 3” in diameter, including flat, port, hinged, child-resistant, continuous thread, twist top, metal lug, tilt top, and tamper-evident varieties

- Process bottles 1-12” in height with varying shapes, including round, square, rectangular, oblong and F-style

- Process up to 90 ppm

- Optimize floorspace with a 73” X 75” footprint

- Fit with existing conveyors or be supplied with an integrated conveyor

- Run remote diagnostics through ethernet

Other standard features include a light tower indicator, a container counter and an integrated hopper/elevator sorter. Available options include a crooked cap/high cap sensor with reject; a cap lining sensor; custom chucks; 21 CFR Part 11 compliance; and spare parts kits. The machine is available in single and dual-head formats.