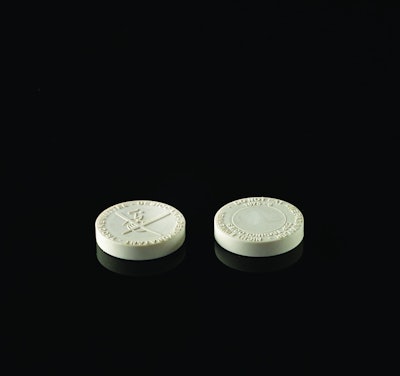

CSP Technologies, Inc. introduced an active scavenging solution that can be integrated directly into primary containers to protect oral solid dose (OSD) products from moisture and oxygen absorption.

Suitable for nearly any typical OSD container, Pharmapuck™ scavenging devices can be integrated into bottle tops or dropped into containers to counteract the introduction of volatile organic compounds in packaging headspace—an occurrence that can lead to displeasing odors or even reduced efficacy or shelf life.

Pharmapuck has the potential to set a new industry standard by providing pharmaceutical manufacturers a foolproof solution to protect their products and prevent misuse by consumers. Its molded-in desiccant eliminates the risk of breakage or spillage associated with sachets and canisters.

Pharmapuck scavenging devices also provide added design flexibility and branding options such as custom coloring, and laser or ink printing to enhance customer awareness and safety. Pharmapuck devices are available in ultra-low particulate formats for high-sensitivity drug applications.

Key benefits of Pharmapuck include the following:

• Durability: Enhanced cleaning and sterilization capabilities, to perform in the most demanding environments required of pharmaceutical packaging

• Product stability: Molded-in desiccant eliminates risk of desiccant breakage or spillage associated with sachets and canisters

• Consistent customer experience: Controls odors and release of aromas

• Design flexibility: Ability to be integrated into virtually any container

• Visual branding options: Custom coloring, laser or ink printing for enhanced consumer awareness and safety