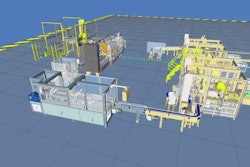

Its compact, reduced machine footprint allows for efficiency in utilizing production room space.

Transfer of the complete syringes to the downstream machine is performed by means of a compact, original system. Both the syringe barrel and the plunger rod are positively handled along their complete path on the machine.

Despite the reduced footprint, production speed is high, thanks to rotary continuous-motion principles and the compact inserting/screwing head. HASTA guarantees 200 or 400 rod insertions/min, depending on the chosen production speed. HASTA offers the upgrades to the faster speed even after the machine is delivered.

The machine modularity concept allows the choice of various configurations: HASTA is mechanically pre-engineered to accept a back-stop inserting unit, even after machine delivery. This pre-engineering allows for addition of the back-stop either before or after the rod insertion into the barrel, depending on the type of back-stop to be used. HASTA can be upgraded with an additional module to insert the Safety Device. It is also possible to prevent the syringe barrel infeed, if the relevant plunger rod is not present. An additional module composed by conical wheels enables to cope with the height of the downstream machine, if needed.

HASTA incorporates a print-and-apply labeler, inclusive of vision systems to check the data printed on the label, the correct alignment of the label on the syringe barrel, the preprinting of the label (sampling check): the autonomy is up to 30.000-35.000 label applications, depending on label size.

The correct insertion height of the rod into the barrel is checked by a laser. It is possible to check coloured rods, with ejection in case the colour is not correct. A second print and apply labeler can be added to avoid machine stops due to the reel replacement time. It is possible to prevent label printing if the rod is not inserted to the correct height.

The machine is provided with a user-friendly operator interface (HMI) for machine conditions check, production data, and to set up the operation parameters, with size parameters recall. The validation system and the relevant documentation are based on the model proposed by GAMP5 Guidelines.

Transfer of the complete syringes to the downstream machine is performed by means of a compact, original system. Both the syringe barrel and the plunger rod are positively handled along their complete path on the machine.

Despite the reduced footprint, production speed is high, thanks to rotary continuous-motion principles and the compact inserting/screwing head. HASTA guarantees 200 or 400 rod insertions/min, depending on the chosen production speed. HASTA offers the upgrades to the faster speed even after the machine is delivered.

The machine modularity concept allows the choice of various configurations: HASTA is mechanically pre-engineered to accept a back-stop inserting unit, even after machine delivery. This pre-engineering allows for addition of the back-stop either before or after the rod insertion into the barrel, depending on the type of back-stop to be used. HASTA can be upgraded with an additional module to insert the Safety Device. It is also possible to prevent the syringe barrel infeed, if the relevant plunger rod is not present. An additional module composed by conical wheels enables to cope with the height of the downstream machine, if needed.

HASTA incorporates a print-and-apply labeler, inclusive of vision systems to check the data printed on the label, the correct alignment of the label on the syringe barrel, the preprinting of the label (sampling check): the autonomy is up to 30.000-35.000 label applications, depending on label size.

The correct insertion height of the rod into the barrel is checked by a laser. It is possible to check coloured rods, with ejection in case the colour is not correct. A second print and apply labeler can be added to avoid machine stops due to the reel replacement time. It is possible to prevent label printing if the rod is not inserted to the correct height.

The machine is provided with a user-friendly operator interface (HMI) for machine conditions check, production data, and to set up the operation parameters, with size parameters recall. The validation system and the relevant documentation are based on the model proposed by GAMP5 Guidelines.

Companies in this press-release