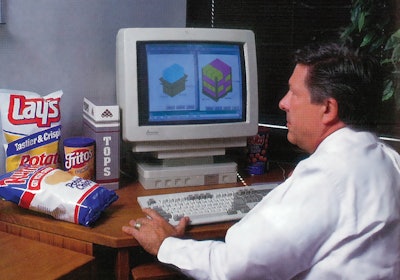

Pete Carrothers, then VP of logistics at PepsiCo, astutely recognized the compounding effect, over time, of maximized loading densities in everything from primary package in a case to pallet configurations in a trailer. As an early adopter of TOPS pallet pattern software, he said, “the difference between 16 bags per shipper and 18 per shipper can mean a million dollars a year.” Twenty-five years on, software for packaging palletization and packing optimization is ubiquitous, inexpensive, and simple compared to CAD/CAM programs like SolidWorks or Autodesk. But it took a few desktop pioneers to recognize and apply the technology for packaging and logistics.

Also of note in this 1994 article is what PepsiCo then called its Project Iberia, an early example of what we’d now call global harmonization. Remember, 1993 marked the advent of the European Union. Until then, neighboring Iberian nations Portugal and Spain had disparate, independent distribution systems in place. But when crossing national borders in Europe became akin to crossing state lines in the U.S., Carrothers and PepsiCo began to see opportunities to standardize case sizes, reduce corrugated, and capitalize on economies of scale.