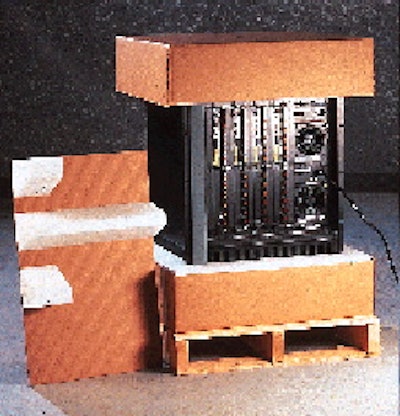

In the initial months, 20% of the shipped products, weighing between 50 and 125 lb depending on the model, were returned due to shipping damages. Faced with repair costs exceeding $1ꯠ per unit, Pittsburgh-based FORE needed a fast package replacement. Materials supplier Tuscarora (New Brighton, PA) was chosen to design a multi-material pack that accommodates the product's various configurations. The package was designed, assembled and completed in a matter of days. It consists of die-cut extruded polyethylene foam end caps, with a density of 2.2 lb/cu', glued to top and bottom corrugated paperboard trays; a corrugated face insert to which is glued EPE with a density of 4 lb/cu'; and a surrounding half-slotted container-made of 350#-test, B/C-flute doublewall corrugated-secured to a wooden pallet. Protective corner posts and steel straps complete the package. According to FORE manufacturing engineer Rodger Fletcher, the new package has saved FORE "in excess of $250ꯠ in repair costs over the past year alone." Packages come pre-assembled on a just-in-time basis, saving time, labor and warehouse space.