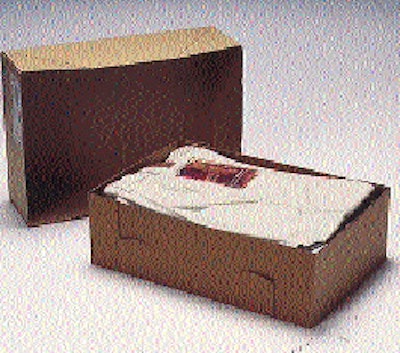

The unprinted, telescoping-style cases, which are erected and folded manually from die-cut blanks without tape or glue, were altered in design by Macmillan Bathurst (Mississauga, Ontario, Canada) to use 20% less board material than the old cases for a total cost savings to Levi Strauss of 5.3%. But that's not all. The old boxes were awkward and time-consuming to erect. With the new design, workers simply lock the cut-away corners of the end panels into die-cut slits in the side panels, speeding assembly by 10%, estimates Don Somerville, Levi's Edmonton production manager. By altering the size and layout of the sides, the die-cut blank sheets are smaller than the old design yet maintain Levi's internal dimensional requirements once the case is erected. The friction-fit lid did not change. Cases are automatically strapped after they're lidded. The new design, in use for about a year, is made from 150# overstrength B-flute, which MB says is the equivalent of 200#-test board. And since the boxes aren't glued or taped, they can be knocked down and erected multiple times, a feature that benefits Levi. Made with 30% recycled content, the container garnered an Envirowise award in the Packaging Assn. of Canada's 1995 competition.