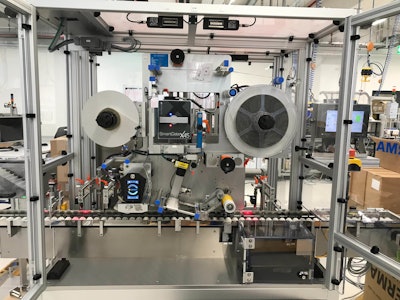

The HERMA 252 M features HERMA’s H500 Label Applicator – which Norwalt utilizes on its high-speed assembly lines – and Norwalt’s product handling systems, which support a broad range of HERMA’s labeling systems for the pharmaceutical sector. The combined system labels at 30 products/min and accommodates containers 12 to 30mm in diameter.

Offering a look into commercial applications, the system on show was similar in design to a line recently supplied to a major US-based pharmaceutical contract manufacturer. In the system on show, “glass tubes are picked from trays using a robotic arm, and placed onto the labeling system’s infeed. Products are then transported to the labeling station, where a wraparound label is applied to each tube,” per a release from Herma. “Labels are printed with a barcode and lot/expiry information, and a vision system inspects the print, rejecting any label deemed out of specification. Finally, products are checked for label alignment and, in the full production version of the system, rejects are segregated from good products, which are then re-trayed.”