Founded in Italy around 1680, Farmingdale, NY-based D’Addario & Co., Inc. began as a provider of musical instrument strings, and over the centuries has grown through acquisition to now provide a range of musical accessories and instrument components. According to Steve Santoro, Automation Engineer at D’Addario, “service and quality are the main reasons D’Addario enjoys success today.”

D’Addario operates three facilities in the U.S., each focused on different product categories. In Farmingdale, the company packages strings, drumheads, and accessories. Beginning five years ago, D’Addario began a transition from blister packaging for its Planet Waves-brand musical accessories to elastic staple systems from Avery Dennison, supplied by Texpak.

“Blister packaging was used for Planet Waves products since the company was acquired 12 years ago,” says Santoro. “The downsides of blister packaging included the need for expensive two-part cavity fixtures for each product, heat transfer affecting the color of the cards, and lots of bulky blister stock.”

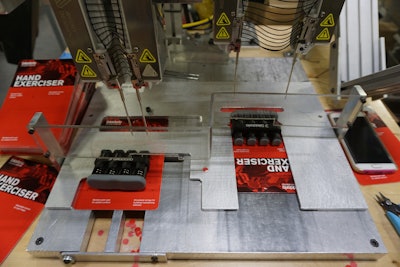

In 2010, D’Addario installed the first of eight Avery Dennison IndES® Elastic Staple® Systems in its Farmingdale plant, with the last system purchased in 2015. The units are installed in four work cells that package 50 different accessories—with that number continuing to grow. Among them are products such as tuners, hand fitness tools, and cables. “Now, 90 percent of the packaging for those products has been converted to elastic stapling,” says Santoro.

Less expensive and quicker process

With the IndES system, products in a variety of shapes and sizes can be attached to a flat card surface via strong, pliable elastic staples that can handle product widths from 15 to 150 mm. The IndES can be used as a standalone system or can be integrated into automated, high-volume packaging lines. According to Avery Dennison, the IndES can produce up to 450 pieces/hr, versus 129/hr for a paper twist tie with adhesive tape, 180/hr for a clear polyvinyl chloride strap, and 257/hr for a plastic twist tie.

Explains Santoro, there were several reasons D’Addario switched from blisters to elastic staples. The main motivators were the reduced amount of plastic going to landfill and the cost-savings opportunities. The IndES is cheaper than alternative packaging systems, offers quicker changeover from one product to another, and features simpler and less-expensive fixtures, he says. In addition, consumers like to touch and feel the product, and with the elastic staples, they can even try the features of some of the products.

To package a product using the IndES, an operator first takes a ¼ x 8 x 14-in. fixture plate that has the shape of the product cut into it for part orientation and places it on the machine with two pins and one clamp screw. The operator then adjusts the needle spacing with a ruler and changes the staple ribbon to the correct size per a product chart. Once setup is complete, the operator slides a backing card into a pocket cut into the fixture. Product is then placed on the card and oriented to the cut shape in the fixture, after which the operator presses two hand-control palm buttons to begin stapling. The card with product is then slid out of the first position and into the second position for a second staple. Most D’Addario products require two staple positions, Santoro notes.

Finished packages are packed in shipping cases in an average quantity of 10, with the stapled backer cards acting as a buffer to protect the next product. Says Santoro, D’Addario has not had any significant problems with damaged product during transportation since it began using elastic staples.

System hits the right note

While Santoro says the labor savings realized by the IndES system is negligible when compared with blister packing, D’Addario is saving money with the elimination of the blisters and the need to heat-seal the blister card. The company is also saving warehouse space, and the appearance of the stapled packages is far superior to the blister packs at retail, where formerly the bright lights used to reflect off the packaging.

“From what I am told, response from consumers has been positive,” says Santoro. “People like to see the actual product, rather than an image on the package.

“IndES met our needs for less packaging material and a ‘touchy, feely’ package, and most important, it addressed our environmental concerns.”