Among the packaging machinery OEMs that have moved from pneumatics to servo motors for their motion axes is Multivac, a leading maker of thermoformers and tray sealers used in a wide variety of food, pharmaceutical, and other consumer packaged goods applications.

“Servo technology increases controllability and reduces noise emission. These systems also help us to increase the number of production cycles,” says Guido Spix, Chief Technology Officer at Multivac. He adds that his firm’s use of motion control solutions from Kollmorgen reduces energy consumption, increases overall machine effectiveness, and improves safety of packaging processes.

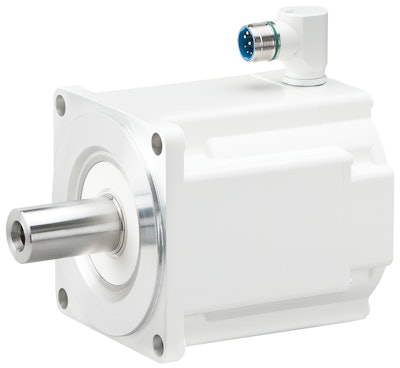

Compared to traditional, mostly pneumatic lifting units, the new lines of Multivac machines utilize a motor-gearbox combination to deep draw the forming web and heat seal the lidding material. These units utilize a knee-lever mechanism to lift the molding tools, some of which weigh several hundred kg. They withstand the high bonding pressure of up to 20 tons, ensuring the two materials seal securely. Being a strategic motion control partner for Multivac, Kollmorgen implemented a compact unit consisting of an AKM servo motor and a cycloidal gear drive for the lifting axis. Kollmorgen calculated and selected the optimal motor size and gear drive type in close cooperation with Multivac’s engineering development teams.