Leadership: nothing good happens without it. In the months since PackExpo, the new officers of the OMAC Packaging Workgroup (OPW) have begun to demonstrate what good, business-oriented leadership can accomplish. The structure is in place to drive home the OPW message to the packaging community. Will it happen?

Big multi-national CPG companies are coming on board, requiring their packaging machines to be built using PackML. Rob Aleksa of P&G says, “We are living the benefits.” Early adopters within the machine building community are testifying to the benefits. Jack Aguero of Pro Mach says they see real advantages for their field service technicians. The technology providers like Rockwell, Siemens, Bosch Rexroth and B&R are prepared with white papers, software, and guidance. Systems integrators have begun to develop expertise. Kirk Weiss of Stone Technologies says PackML reduces their risk, simplifies their applications, and allows them to add value for the customer sooner. PMMI is lending its support and providing forums for discussion. PMMI’s view is that adoption is a decision made by each company, but PMMI encourages members to move forward with new innovation. The key now is to get past the technical discussions and misunderstandings and help everyone understand why the OPW’s Connect-and-Pack approach is a business win for each constituency and good for manufacturing in general.

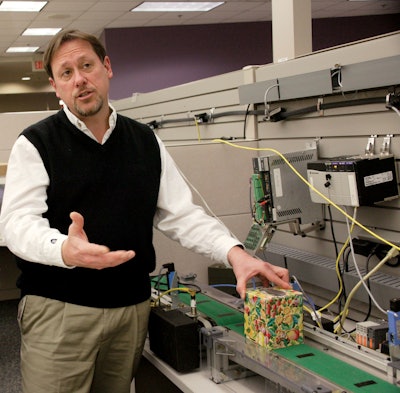

Dr. Bryan Griffen became Chair of the OMAC Packaging Workgroup in 2011. As group manager for electrical and automation systems at Nestlé’s world headquarters in Vevey, Switzerland, Griffen has brought to OPW the kind of leadership skill that gigantic multi-nationals instill and expect from their managers. His position has also enabled him to tap other Nestlé resources and to make their volunteer OPW activities part of their day job. Three of the nine OPW Pack Teams and subgroups are led by Nestlé personnel. Five of the teams are led by CPG companies, including Pfizer and Church & Dwight, with the remaining four teams led by technology providers or system integrators. It is unfortunate that none of the team leaders are machinery builders, but OEMs are actively participating on the teams and the Executive Committee. Tom Egan, vice president, Industry Services & Membership, serves as the PMMI focal point and mentor for the OMAC teams.

PMMI has stepped up to provide administrative assistance to all of OMAC (the Organization for Machine Automation and Control), both the packaging and machine tool working groups. PMMI members are at the same time machine tool users and packaging machine suppliers, so both of the groups have relevance to them. Egan sees potential cross benefits between the groups and thinks there would be benefit to having a bigger informational exchange amongst all the parties. He doesn’t claim to know how many PMMI members have adopted OPW guidelines because no survey has ever been done, but off the cuff he can name at least half a dozen. Pearson Packaging made a presentation about their new machines that employ PackML at PMMI’s members-only MarketTrends Conference. PMMI members, like end users, include watchers, quiet adopters, and active, vocal adopters. PMMI’s joint sponsorship of the Alliance for Innovation & Operations Excellence (AIOE)—the Grocery Manufacturers Association is the other sponsor—raises the possibility of being able to communicate about OPW with more end-user executives. The AIOE, just completing its first year of operations, already has participation from 75 consumer packaged goods (CPG) companies. PMMI’s technical training program may also be something that OMAC can leverage as it works to exchange best practices in the use of its work products.

Many have noted OMAC’s lack of progress over the last couple of years. Those on the outside are unaware of how much energy was consumed by the group going through the ISA/Automation Federation divorce and finding a new friend in PMMI. The separation was executed in an honorable way, but not without significant disruption for an all-volunteer group. With support from PMMI firmly established, OMAC may not be able to make up that lost time, but will at least be able to accelerate activity.

Good leaders see to it that everyone is moving toward a common goal. OPW has a clear mission statement that speaks to the business results to be achieved by end users: To be the guidepost in the packaging industry leading to a more unified automation solution that improves packaging line efficiencies, reduces the capital and operating costs associated with packaging lines, and promotes faster time to market.

A two-fold strategy balances the technical development and the need to communicate and convince companies to adopt the work. On the technical side the stated strategy is: Develop the technical specifications, tools, and methods that make up the Connect-and-Pack Standards and that facilitate attaining the greatest value from packaging automation systems. Work with other industry automation organizations to align standards and methods used in packaging equipment design. And on the marketing side the strategy has evolved to: Increase adoption of the Connect-and-Pack Standards across industry, including End Users, OEMs, Systems Integrators, packaging associations, and educational institutions through providing concrete value propositions that positively affect the business and human aspects of the adopting entity. OMAC Connect and Pack is a registered trademark used to describe the OPW work products and to convey the concept of plug and play that is central to the OMAC vision for machinery.

If successful, OPW’s vision is: To maximize the business value of packaging machinery through the implementation of automation standards that lead to improved flexibility and increased capability, while improving safety and reducing the total cost of ownership. The group will recognize this success when packaging industry norms are aligned with the Connect-and-Pack philosophy. End users will routinely specify OPW standards when purchasing machines, machine builders will offer compliant solutions as their preferred implementation, systems integrators will provide tools that leverage these standards to address customer business needs, and technology providers will offer platforms, software, and tools that ease implementation of OPW requirements and promote interconnectivity with all OPW-compliant technologies.

Where the work is accomplished

To address the technical and marketing areas, PackTeams have been put in place. Using project management techniques, the teams have been tasked with creating their own mission statements, setting milestones, and reporting on status against those milestones. Most teams have completed an early milestone, have additional ones to complete over the summer, and have a significant milestone corresponding with PackExpo 2012.

There are five OPW technical teams: PackConnect, PackSoft, PackML, PackSpec, and PackSafety. These teams—comprising representatives from end user, OEM, SI, and technology provider companies—create, test, and demonstrate the OPW deliverables. PackConnect was one of the original OPW PackTeams, so-named in the Summer of 2001, but in existence for at least 1 year prior under the banner of the Architecture and Connectivity Sub-team of what was then called the OMAC Motion for Packaging Workgroup. At that time and up until OMAC became part of ISA, OMAC stood for The Open Modular Automation Controls User Group. The initial thrust of the OMAC effort was in the machine tool area driven by Boeing, General Motors, and other discrete manufacturers. The OMAC packaging initiative was initially aimed at facilitating the adoption by the North American packaging machinery industry of coordinated multi-axis motion control technology.

The PackConnect team’s first significant deliverable was a series of architecture documents that showed the multiple ways in which a motion control system could be configured for a packaging machine and explaining the pluses and minuses of each. The different types of field buses (I/O, motion, field, cell, enterprise) were identified, and characteristics of the competing motion buses were explored. At the time, this was relatively new information for many end users and OEMs in North America.

Once the team established how machines might be connected, both internally between devices and externally between machines and higher level systems, the question arose about what types of data might be interchanged. Fred Putnam of the Markem Corporation, and an early member of the PackConnect team, suggested that the group spend some time on this topic. The result was the establishment of a new sub-team that produced the first version of PackML, published in The Guidelines for Packaging Machinery Automation v1.1 in October of 2001. The slogan was, “If a packaging machine could talk, what language would it use?” The answer: Packaging Machine Language.

Along the way to developing PackML, the teams developed another useful document, released in September 2001, to describe the levels of integration that a packaging line might utilize. These included Line Type 1 where each machine is essentially stand-alone; Line Type 2A where machines are interlocked through discrete or analog inputs and outputs; Line Type 2B where machines are interlocked over a network that could also share data among the machines; Line Type 3 where machines are coordinated over a network by a supervisory controller; and Line Type 4 where in addition to the supervisory system, the machines exchange real time data with transactional data at the enterprise level. This work illuminated the functions of the buses defined by PackConnect and gave guidance to PackML regarding the kinds of things that one machine might want to say to another or to some sort of host.

Today, PackML provides a generic model of machine modes and machine states that can be used to describe the operation of any packaging machine. Modes and states that are not required by a particular machine may be ignored. A huge advantage of such a model is that it harmonizes the terms that operators learn and use to describe what is taking place in production. It eliminates the confusion created when one person uses the term running to mean that the machine is dry cycling and another uses it to mean the machine is producing product. Plant managers have enough to deal with, having operators that speak different native languages, without having the added complexity of the same words meaning different things on different machines. Frequently this very simple concept is lost in the detailed and complex technical work that goes on under the covers to produce this simple, elegant result. A similar complaint frequently heard is that the stack lights used to announce machine states have no uniform color standard. Red on one machine may mean yellow on another. This is a problem that PackML may be used to solve.

In addition to machine modes and states, PackML defines a set of tags. Tags are essentially named buckets that contain information that may be exchanged by one machine with another or with a host. This information may be the latest alarm issued by the machine, the status of a variable speed drive, or the number of products processed by the machine since some defined time or event. If machine A needs a certain piece of information from machine B, it requests the contents of the appropriate bucket. It doesn’t need to know anything about the software in the machine that creates that information, just the bucket name that contains it. If every machine uses the same bucket names, the conversations can proceed efficiently. Machines may be interlocked by exchanging tag values, and host systems can calculate the OEE (Overall Equipment Efficiency) of a machine or line simply by referring to the appropriate tags.

PackConnect’s mission at this time was: Define technological requirements to cover line integration, focusing on horizontal (machine to machine) and vertical (machine to MES) communications. In other words, what methods should be used to exchange PackTags between machines and between machines and a higher level controller? Despite early criticism coming out of Europe that OPW was “an American thing,” the first meeting of the reinvigorated PackConnect team was held among thirteen team members in Europe, led by Thibaud Kozicki of Nestlé. The team’s next task is to complete some market research to more fully define the required scope as seen by the four constituents (users, builders, SIs and technology providers).

The demonstration projects and successful real world implementations of PackML have been done using different network standards and different communications protocols over those networks. For example, Nestlé completed a test using Weihenstephan protocol over Ethernet (see www.bit.ly/pwe00395). OMAC created their 2007 PackExpo demonstration project using OPC over Ethernet.

It is not PackConnect’s goal to drive a user off of a preferred automation network to some new network. It is more likely that they will specify one or more communications protocols, like OPC, that may be used for the interchange of tag data. The team will look at and evaluate potential solutions, pilot one or more solutions, and return a recommendation.

The PackML team’s current mission is: To enable creation of consistent packaging automation solutions by functioning as the unifying force among automation solution providers, original equipment manufacturers, and end users in the packaging industry and by helping to create core definitions and usable common machine language for the technology developers.

Over the past several years, this team has successfully harmonized their work with that described in the standard ISA-S88 Part 5 (Make2Pack) and the Weihenstephan Standard—Part 2 Version 2005. The harmonized work has been issued as ISA Technical Report ISA-TR88.00.02-2008 Machine and Unit States. A full description of this process may be found in the PackML Wiki on the Wikipedia Web site.

In 2009, Procter & Gamble developed a PackML Implementation Guide and a software template with help files and provided a non-exclusive royalty-free license to OMAC that issued this through the PackML team. The OMAC Implementation Guide is available for download at the OMAC Web site, www.omac.org. Many technology providers have also developed white papers, implementation guides, and software that are available at no charge to their customers. An unknown number (more than dozens, less than thousands) of machines containing complete or partial implementations of PackML have been delivered over a period of years from and to various parts of the world. Some have been at the insistence of end users such as SAB Miller or P&G. Others have been at the desire of the machinery builder, not all of whom will advertise the fact that their underlying structure is PackML.

Now the PackML team is expanding its member base in order to complete the PackML MES Definition document by June of this year, coordinate with other OMAC groups, and complete an approved usable solution by the end of the year. This exercise has basically been to validate that all of the necessary tags and structures are in place to complete an implementation of a Manufacturing Execution System. Based upon their findings, the team is recommending minor additions to the technical report in areas such as part processing counts, starved and blocked administrative tags, and added examples of key performance indicator calculations. Having reviewed a draft of the changes, it appears that about one total page of additions is being suggested to what is a 110 page document.

PackSoft is the last of the original OPW PackTeams. PackSoft has always been closely associated with PLCOpen. In July 2001, shortly before the release of version 1.0 of PLCOpen’s Motion Function Blocks, OPW issued a position statement encouraging development and evaluation of the PLCOpen motion function blocks, which are based on the international standard for PLC programming languages, IEC61131-3. As recorded in the statement, this was in the quest for an interoperable, portable, multi-vendor solution for motion programming software. In the ensuing years, I find no record of any new software guidelines or position statements having been issued by OMAC, although IEC61131-3 is cited as being followed in certain examples within the PackML Technical Report. PLCOpen has issued several clarifications and additions to their original document with the latest being version 2.0 issued in November 2011.

The official mission of PackSoft has remained the same since at least 2003: To develop guidelines for machinery programming languages to ease learning, support transportability of software across platforms, and allow continuing innovation. Eelco van der Wal, the PackSoft team leader and managing director of PLCOpen, operating out of the Netherlands, has suggested a refresh of this mission: To develop guidelines for efficient software development for packaging applications over the product life cycle. These guidelines will facilitate the implementation of those applications on multiple platforms; support the training of operating and maintenance staff; and create the basis for flexible packaging machines by harmonizing the look-and-feel of the different controllers used in productions lines. This similar statement seems to acknowledge that full transportability may be a stretch, but that a common look and feel would in fact be a good thing and an improvement within the industry.

PLCOpen’s work is paralleling OPW’s in that they are also focusing on safety, ease of commissioning, and transparent access to information—in PLCOpen’s case, via OPC UA. According to Bill Lydon, PLCOpen’s North American representative, after the OMAC packing meeting during the February 2012 ARC conference it was agreed to jointly pursue definition with PLCOpen of function blocks using PackTags to simplify the conformance to PackSoft, PackML, PackSyst, and PackConnect requirements.

In response to needs identified by OPW members, Griffen and his executive committee have established two new technical teams within the past year. We’ll pick up that thread of the OMAC Packaging Workgroup story in the May issue of Packaging World.

Keith Campbell of Campbell Management Services LLC is a regular Packaging World blogger and occasional contributing editor. He can be reached at [email protected]