Operating at the very front end of packaging development, brand marketers and designers are in the driver’s seat in 2008 and beyond to strongly influence opportunities for creating packaging that positively impacts both purchase decisions and the environment. That’s because much of the impact of materials is established during package design.

But with all the confusion that exists around the very broad term “sustainable packaging,” creative teams lagging behind the curve of the sustainability wave might be putting excessive pressure on themselves. They might be operating under the belief that they have to play catch-up with the early pioneers by quickly creating packages that renew resources, curb energy use—and oh yeah, stay “on brand.”

Be forewarned, branding and package materials experts say. Such a breathless, first-take approach to marrying sustainability and design is not only likely to fail, but hasty packaging decisions also could have the opposite of their intended effect. If that’s the case, how can product manufacturers make decisions with real environmental impact? And how can they weave sustainability as an effective component into their marketing strategies?

John Bernardo suggests starting by taking incremental steps and building upon each success rather than striving for quantum leaps. “You don’t have to feel pressure to immediately create a sustainable package. You want to begin to move in that direction over time,” says Bernardo, a leading advocate for sustainable packaging. He managed Albertson’s resource conservation program for seven years before creating a consultancy called Sustainable Innovations.

A good first step is to establish a general working definition of sustainability.

“There is no universally accepted definition for sustainability, but basically, creative-team managers can’t go wrong by saying, ‘Let me have the resources I need to be profitable today without draining their availability for people to be profitable tomorrow,’” Bernardo explains.

He recommends three areas as solid places to start incorporating a sustainability mind-set into package design: Improve materials sourcing, change the package size, and let consumers know what sustainability efforts are being made and why. Some of the early leaders, such as Aveda, Unilever, and Coca-Cola, are companies from which to draw inspiration.

Improve materials sourcing

If the goal is to make the package an asset after it is unloaded at the store, allow time to do it well, John Delfausse, chief environmental officer, corporate packaging at Estée Lauder and vice president of package development for Aveda, said in a presentation earlier this year at The Packaging Summit. “Designing for the environment is a journey,” he said. “Don’t think you’re going to get there tomorrow or even the next day. Don’t wait until you have the perfect sustainable solution. Just advance things little by little.”

A logical place to begin on the materials sourcing journey is to state to vendors your intention to use a higher percentage of recycled content and less virgin material. Challenge suppliers to provide innovative solutions, and assess your company’s risk tolerance to determine how much creative freedom designers will have, Delfausse said.

In health and beauty aids, Aveda’s approach—it has evolved over several decades—provides one blueprint for sustainable design. The company strives to design packages with materials that can be reused, recycled, or composted as it creates “eco-chic” consumer brands. Ashley Rosebrook, Aveda executive design director, said in a presentation earlier this year with Delfausse at the Fuse: Brand Identity and Package Design conference that Aveda operates a dedicated sustainability team that balances end-of-life issues with brand value and the need to stay on budget.

“If you can save money doing it, people hop on the bandwagon and support the project,” Rosebrook says.

Aveda’s sustainability team places primary emphasis on environmental considerations. Cost is second, and design is third. Working within that hierarchy, Aveda’s creative teams carefully weigh decisions concerning materials selection.

Delfausse added that the Aveda approach merges multiple packaging metrics using an internally developed scorecard. The analysis includes the total life-cycle impact on each material. Teams evaluate each material as it’s sourced, when it’s used in packaging, and on through to disposal.

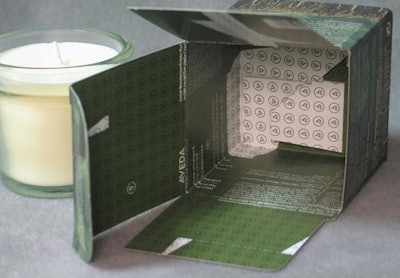

The Aveda Lights the Way To Earth Month limited-edition candle provides a snapshot into this integrated design approach. The candle packaging uses an extensive amount of earth-friendly materials and maintains its elegance in the health and beauty aids aisle. The candle celebrates Earth Month, and each candle’s aroma and formula come entirely from certified organic ingredients. Packaging materials also support environmental stewardship.

The candle nests in a 95% post-consumer recycled (PCR) glass container. The carton is printed with soy ink on 55% PCR paper.

On the processing end, Earth Month candle cartons are wind-energy-certified. Aveda purchases the energy from Windsource Energy Systems to power its primary manufacturing and its distribution center in Blaine, MN.

Aveda’s Brilliant brand of health and beauty products provides another example of designing for the environment. The brand switched from cobalt blue glass, heavy gold metal screen printing, and a large overcap—some elements couldn’t be recycled—to tubes containing 35% PCR materials. Multifold labels on Brilliant jars and bottles, printed in five languages, eliminate the need for cartons. Jars and caps use 100% PCR PET, with the plastic being recycled from water bottles, Delfausse said.

Change (reduce) the package size

Besides looking at packaging materials, also make a case for changing the packaging size. Unilever offers validation that creative teams can balance consumer needs in a product category with a reduction in packaging materials, fuel, and energy. At the same time, sales can increase, and a brand can further solidify its reputation as a pioneer in its category. The key is to take a “big picture” approach when integrating sustainability and design. Opportunities can emerge to treat the earth right and also enhance consumer experiences with a product.

Unilever did just that when developing All Small & Mighty laundry detergent as an answer to consumer convenience. First, the company created a 3X concentrated formula. Then it introduced an HDPE spouted bottle that contains at least 25% PCR content and is recyclable. The new bottle is smaller, lighter, and easier to use than the giant bottles used for 1X concentrates, which devour shelf space in the laundry detergent aisle and at home.

All Small & Mighty’s sales of $145 million during a recent 52-week period exceeded Unilever’s expectations. The Nielsen Co. reports that the brand’s trial rate is growing, and its repeat sales rate is one of the highest ever in laundry detergent. Besides increasing consumer perceptions of brand value, the new product and packaging are delivering the following benefits:

• The All parent brand cements its reputation as an innovator in laundry detergent by creating the concentrates subcategory.

Consumers get a smaller, more convenient-use package that contains detergent providing the same cleaning benefits they associate with the All brand.

• Retailers gain additional “ring.” More of the smaller bottles fit in the same shelf footprint that retailers give to the larger detergent bottles, thereby lowering stocking costs and reducing out-of-stocks.

• The environment benefits because less material is used to produce and pack the product, and less fuel is used to transport it.

“Put another way, a universal move to 3X concentrates would save 26% more plastic and corrugate packaging than using 2X concentrates,” says Helayna Minsk, Unilever’s marketing director for laundry products.

All Small & Mighty didn’t start out as a sustainable packaging endeavor. Product and packaging teams at Unilever were initially focused on improving consumer convenience.

“In addressing that insight, we found that we could also address consumers’ increasing interest in green products and initiatives,” Minsk says. “The ingenuity behind All Small & Mighty was consumer insight. In focus group tests, when acting out their laundry routines, consumers repeatedly pantomimed struggling with oversized and weighty detergent bottles.

“In designing the bottle for All Small & Mighty, we took our answer to consumers a step further than just making a smaller product. We pioneered an ergonomically designed bottle that better fits a woman’s hand and offers a no-slip grip, even without a handle.”

Brand marketers retained an extensive billboard, despite the bottle’s smaller size, by opting for a full-body OPS shrink label, from Fort Dearborn, printed gravure in six to eight colors. The shrink label is not only unusual in the category, but it also provides ample room for icons to educate consumers about the value of the smaller product volume—the standard All Small & Mighty bottle is 32 oz and can do the same number of loads of laundry as a 100-oz bottle of 1X concentrate.

“The shrink wrap also allows for more vibrant colors and is easily changeable, giving us the latitude to quickly customize labels for new variants and seasonal promotions,” Minsk notes.

Perhaps most important in the smaller package/consumer convenience equation, the new PP cap signals that smaller is better. Unilever’s research determined that 96% of liquid laundry detergent users dose with a cap, so Unilever reduced the cap size 15% (and the bottle weight by 11%) as an intuitive way to educate consumers about how relatively little concentrated detergent is required to get clothes clean. The new cap is one-third the size of standard laundry detergent caps.

Unilever sells the “less is more” message elsewhere on the bottle while also making the container easier to use. In the absence of a handle, which would have required the use of additional plastic resin, the top of the bottle is narrowed and shaped to fit a woman’s hand. Just above where the bottle narrows, a “lip” prevents the bottle from slipping out of the hand.

Environmental impact has been significant. For Unilever, the smaller detergent bottles have saved 25,000 gallons of diesel fuel, 3.5 million grams of plastic resin, and 18.5 million square feet of corrugate. In addition, 1.4 million fewer shipping cases and 35,000 fewer pallets have been handled. For Wal-Mart, which launched All Small & Mighty, the savings include 50% fewer out-of-stocks and lower labor costs, says Matt Kistler, Wal-Mart vice president, package and product innovations.

Tell them what

Bernardo says there is a third area in which product manufacturers can make an immediate impact in the push for sustainability. As you source more earth-friendly materials or change the package size, be sure to let consumers know what sustainability efforts are being made.

Coca-Cola is one company to watch. In September, the company announced it would invest heavily to support recycling in the United States. As part of the effort, Coca-Cola has a stated objective that 10% of all its plastic bottles will use recycled PET, says Marilyn Baker, manager of global quality standards at Coca-Cola. The company needs to find more sources of recycled PET soft drink bottles to meet this goal. But Coca-Cola is signaling its intent to support recycling.

These examples from Aveda, Unilever, and Coca-Cola are evidence that packaging can be an effective marketing tool, especially when promoting that a package is recyclable or sustainable.

“In business, as in nature, all waste is assets in disguise,” Bernardo says. “Start thinking in terms of the package’s value once the product is gone. Your retailer and your consumer don’t want to have to pay to get rid of it.”