H.D. Smith is following the lead of the Food and Drug Administration, which has identified RFID as a key packaging tactic in fighting counterfeiters and improving drug security. The strategy is simple: If you know where a drug is in the supply chain, you add security.

In its pilot program, H.D. Smith is putting RFID tags on primary packages of Class 2 pharmaceuticals, the drugs most likely to be abused because of their narcotic properties. They are currently among the most labor-intensive drugs for distributors to handle.

“We know this is a technology that is right for our industry,” says Robert Kashmer, vice president of information technology at H.D. Smith. “We know there will be efficiencies from using this technology. We’re not there now, because we’re putting the tags on by ourselves, but it will come.

“We want to look at the product in the supply chain and the authentication portion of the process,” he continues. “To us, it is an important step, and we want to embrace this.”

In the pilot operation, H.D. Smith personnel are manually applying tags to unit packages they sell to a specific group of pharmacies.

The company is using tags from Matrics, Inc. The tags are rectangular, 30 mm by 36 mm (approximately an inch by an inch-and-a-half). Each holds 96 bits of information, enough capacity to carry an electronic product code (EPC). Tags are “read only” with an individual EPC number already coded to each tag. The code is unique to each package and allows each individual package to be identified during its trip through the distribution system.

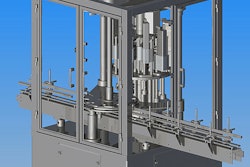

Tagged primary packages go into plastic totes destined for specific pharmacies. In the pilot program, H.D. Smith reads all the individual tags as the tote passes a portal, where a reader, also from Matrics, verifies and establishes the tote’s contents. The company is not currently using tags on totes themselves to aggregate data from the contents inside.

H.D. Smith continues to use bar-coded and human-readable tags on the pharmaceutical packages. Data from those sources provide a baseline of information against which to compare the RFID data and read rates in assessing the technology. The project’s next step will be to install a reader at a retail pharmacy that will receive totes. That will allow assessment of the process through the drug distribution chain.

“One of the biggest advantages of RFID technology is that reading a tag doesn’t require direct line of sight. You don’t have to handle individual packages,” Kashmer explains in describing benefits beyond the bar codes they already have on packages. “RFID is serialized [each package having a discrete EPC of its own], and bar codes are not. We can track the individual bottle. We know exactly where the bottle is at any time. We have recall information.”

The tags from Matrics consist of a chip and an antenna mounted on a pressure-sensitive label. Liz Churchill, director of life sciences solutions at Matrics, says that electronic components are now being put on the labels used at H.D. Smith by X-ident Technology, Duren, Germany.

The pilot program at H.D. Smith anticipates pharmaceutical manufacturers will be applying tags that are part of the human- and machine-readable labels that will go onto primary containers.

“The 2007 goal by the FDA for implementation on RFID tagging on prescription drugs is very realistic,” says Kashmer. “The efficiencies will come in the future when manufacturers put tags on containers.”

The H.D. Smith trial parallels the program being instituted by Wal-Mart for its pharmacies. “We’re doing a similar process,” explains Kashmer. “This is a good control point for us, something we can measure.”

While taking a leading-edge stance, Kashmer also realizes there is reluctance by some in the pharmaceutical supply chain to embrace this technology. “Some people want it to be totally resolved and totally black and white. Those people aren’t ready to commit now. We are resolving some of those issues that are emerging.”

See the story that goes with this sidebar: Package security demands linking of strategy, technology