Lewis & Clark took note of the springs in 1805. By 1881, their waters were described in the local press as having rare healing powers. And then there was that horse in 1979. Its injured jaw bones made a remarkable recovery because the animal drank copiously of the springs’ water, which is naturally rich not only in fluoride but also in a bone-building mineral called strontium.

Now these springs, which flow through the limestone bluffs above Montana’s Beaverhead River, are sending their water to people throughout Montana and soon most of the West. A company called Montaqua Spring Water of Dillon, MT, is making it happen.

Helping, of course, are packaging machines and materials. Also lending a big hand are founder Glenn Hegsted, son David, and stepson Mike Couch. Together they built the 25ꯠ-sq’ bottling plant that captures the mineral-rich water in various container sizes. Their latest addition is a new line for PET bottles in ½-, 1-, and 1.5-L sizes. Capable of 300 bottles/min, it’s the piece of the puzzle that positions the firm to go from being a local curiosity to a regional power.

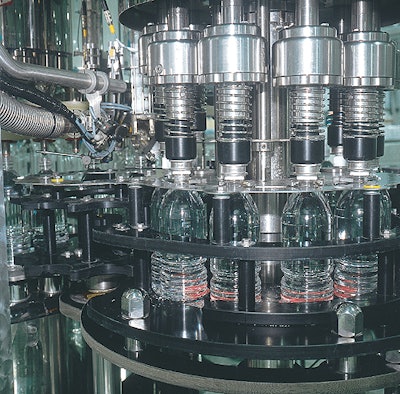

Central to the line is a 24-valve gravity filler from Fogg (www.foggfiller.com).

“We looked at a lot of fillers, but we liked the sturdiness of the Fogg equipment,” says Glenn Hegsted. Sharing the same drive shaft in a monobloc arrangement is a Fogg eight-station capper. Both filler and capper housed are inside an enclosed chamber where overpressured sterile air keeps contamination out.

Depalletizer

Bottles enter the line through a depalletizer made largely in-house. It feeds bottles into the 100 cu’ hopper of a Model NEHHLPE72 unscrambler from New England Machinery (www.neminc. com). This machine’s sorting bowl has a sensor that triggers a signal when it needs more bottles from the hopper. From the sorting bowl, bottles feed into a belt-driven section that orients bottles into an upright position so they can be conveyed to the next machine in the line.

The unscrambler’s low-profile design allows easy access to all parts of the machine should bottle size changes require change parts. The low-profile configuration also means the sorting bowl is always easily visible by operators. And a patented soft-belt transfer system minimizes scuffing of the clear PET bottles. But the quality that Glenn Hegsted seems most impressed by is the machine’s durability. “It’s really built well,” he observes.

Oriented bottles are conveyed to a Bevco (www.bevco.net) rinser. Ozonated water is used to rinse the bottles, which then are conveyed to the filler/capper enclosure.

Just before caps are applied, liquid nitrogen is inserted into each bottle by a dosing system from VBS Industries (www.vbsflex.com). The nitrogen is -196°C when inserted into the bottle. As it warms, it turns to a gaseous state and provides an internal pressure that keeps the bottle from deforming. “We’re dropping 6ꯠ feet in elevation when we leave our plant, and atmospheric pressure increases as you drop in elevation,” says Glenn Hegsted. With nothing inside the bottle to counter the atmospheric pressure, panelling in the bottle sidewalls could be a problem at lower elevation.

Immediately after capping, bottles are conveyed past a laser coder from Markem (www.markem. com). It codes each bottle with a date and production code. “We just didn’t want the mess associated with ink cartridges,” says Glenn Hegsted. “This laser coder works beautifully.”

Tamper-evident shrink capsules are applied by an Axon (www.axon.com) machine. It was purchased, recalls Glenn Hegsted ruefully, at Pack Expo Las Vegas the day before 9/11.

Next in line is labeling. It’s performed by a machine from Germany’s Langguth GmbH, represented in North America by Priority One (www.priorityonepackaging.com). It uses a three-nozzle Nordson (www.nordson.com) system to spray hot melt glue onto the bottle. The bottle then pulls a label from a magazine. The label is wrapped around the bottle, and then another three-nozzle set of glue guns sprays glue on the trailing edge of the label to complete the labeling process.

Cut-and-stacked labels from Inland Printing (www.inlandprinting.com) are 3.2-mil white opaque oriented polypropylene. They’re printed offset in four colors plus an aequeous coating.

“We really like the glossy look and feel of this label,” says David Hegsted. “It stands out dramatically at point of sale.”

Automated secondary packaging

Secondary packaging is as automated as the upstream portion of the line. A Marq (www.marq. net) case erector lifts a stack of case blanks into a pick position, from which a vacuum pickup device grabs one blank at a time and advances it toward the erecting station. Here a second vacuum pick device erects the case into an open position. Mechanical arms tuck the bottom flaps and the bottom is taped.

The erected cases drop onto a conveyor that takes them to a drop packer supplied by Hamrick (www.hamrickmfg.com). The 1- and 1.5-L bottles are packed 12 per case and the .5-L bottles go 24 per case. Out of the drop packer, cases move through a Belcor (www.belcor.com) taper. Palletizing, for now, is done manually. The final piece of equipment in the line is a stretch wrapper from Cousins (www.cousinspackaging.com).

“The wrapper is so easy when it’s time to change the film roll,” says Glenn Hegsted. “It only takes about 20 seconds.”

So what’s next for the Hegsteds and their fledgling firm? A strong focus on expanding distribution throughout the west. Confident their expansion will be successful, the Hegsteds are already evaluating more packaging equipment for the future, notably shrink bundling, palletizing, and—maybe one day—stretch/blow molding.

“We have a rare product and a high-capacity PET bottling line,” says David Hegsted. “Our job now is to make ourselves better known.”