TC Transcontinental Packaging's 100% industrially compostable single-serve coffee pod is accompanied by a 100% compostable mother bag and a fully recyclable paperboard carton containing 65% recycled content. The pod technology, which uses “a high percentage” of renewable, plant-based materials, was a world first in 2015 when it was launched by Club Coffee. The FPA Award recognizes TC Transcontinental for its work with Maxwell House Coffee Canada, a Kraft Heinz Canada brand, which debuted the compostable pods in September 2020.

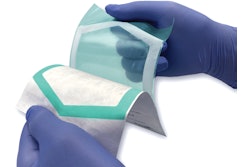

According to TC Transcontinental, engineering the compostable films to ensure their performance and ability to run on existing equipment demanded true collaboration and partnership between its R&D team and the Maxwell House product engineering team. The zero-waste pod, which eliminates the need to separate components before disposal, is constructed of a nonwoven mesh filter made from corn-based polylactic acid bioplastic (supplier unnamed), a ring made from 20% coffee bean husks and PLA, and a wood pulp-based lid. Explains TC Transcontinental, the lidding is a lamination of paper and a compostable sealant, with the paper providing thermal stability and the sealant sealing the lid to the filter and ring.

Disposal of the spent pod, which includes 85% coffee grounds, is a simple process, advises Maxwell House: “Toss the pod into the compost bin, and it will decompose in the nutrient-rich soil.”

To keep the coffee fresh until use, pods are packaged in a mother bag made from a lamination of NatureFlex™ PLA from Futamura and a compostable sealant, with an additional layer of oxygen barrier. To ensure there is no soil toxicity in the composting process of the pod or mother bag, the lidding material and bag are printed using the Extended Gamut 7 flexographic printing process, which TC Transcontinental says “optimizes the amount of ink laydown while pleasingly reproducing the critical brand graphics.” The inks used, they add, have been tested safe for heavy metals and eco-toxicity.

After being real-world tested in a cross-section of composting conditions and processes, including windrow, in-vessel, and static aerated piles, both the lidding material and mother bag were certified by BPI (Biodegradable Products Institute) to meet ASTM D6400 and D6868 standards for industrial composting. Says TC Transcontinental, “BPI ensures that any product they certify is fully compostable—all components—into good compost soil with no toxicity.” The company adds that these packaging components are formulated to break down in a period of approximately seven weeks