This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Velteko has expanded its range of vertical packaging machines to include a machine with a hygienic design. This packaging machine is adapted for use in operations that require higher standards of hygiene and sanitation, and the IP69K certification means it can be cleaned using pressure washing. The VELTEKO WASHDOWN-360 vertical packaging machine can be used in operations with more stringent hygiene requirements as well as anywhere that liquids need to be packaged.

The VELTEKO WASHDOWN-360 vertical packaging machine can be used wherever more stringent hygiene standards are required. This particularly includes the food industry—such as for the packaging of frozen food, meat, fish or sauces - and other operations where liquid or semi-liquid products are packaged in conditions requiring higher standards of cleanliness.

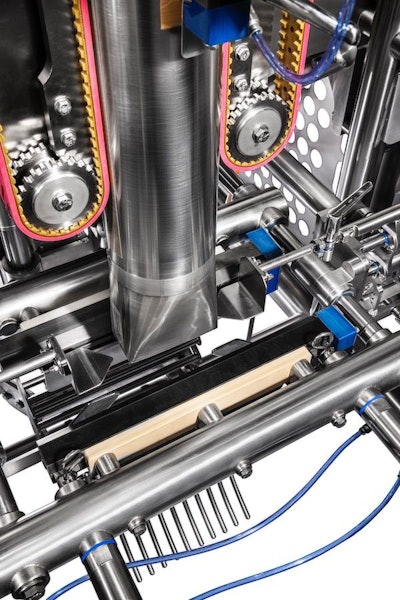

Waterproof and hygienic design

In practice, WASHDOWN machines – the name Velteko uses for this series – are easy to thoroughly clean with pressurised water. Increased hygiene requirements are reflected in the overall design of the machine. "We designed the VELTEKO WASHDOWN series so as to ensure that there are no hard-to-clean spots, such as corners or depressions where liquids can accumulate and bacteria can multiply. The machine also has a minimum of large horizontal surfaces in which water can accumulate," says Tomáš Šmíd from the VELTEKO development department, describing the construction of the machine. He adds that the suitably dimensioned stainless-steel structure and high-quality branded components naturally also result in a machine that will function for a long time and require little maintenance.

Wide range of uses

Despite the design and the emphasis on operational hygiene, the WASHDOWN series retains all the advantages offered by VELTEKO vertical packaging machines. The machine can pack up to 160 bags per minute and can easily handle large, fragile or liquid products. The maximum volume per packed bag is up to 20 litres. The machine can package goods in a wide range of different bags – the maximum width of the bag seam is 360 mm.

Easy to operate

The VELTEKO WASHDOWN-360 can easily be integrated into complex packaging lines following the customer’s specific requirements.