Mark Stenske, Service Manager for Matrix, a ProMach company, used PACK EXPO Connects to demonstrate how the Matrix Bag-in-Bag provides an innovative way to fill single-serve and multiple-serve pillow bags in an overwrap or master bag.

The Matrix Elete Bag-in-Bag machine is essentially two machines in a single frame. In the demonstration, one bagger above was feeding into another below in a single enclosure. In a ground coffee application, the top section packages product into heat-sealed filter paper pouches, and the lower section bags those pouches in metalized film packs. Visible are both rolls of filter-paper film and foil film, one above the other, on the back of the machine. At the front, visible are pull belts advancing the upper filter paper as the vertical seal bar intermittently seals the top, and the end-seal jaws separate each filter-paper pouch, and drop them into a funnel to introduce to the second portion of the machine.

There, on the bottom section, again pull belts advance the film, this time the metalized plastic, with horizontal seals making the end seal and a knife separates each metalized film pouch. All programs are saved into recipes and can be recalled into future runs.

Another application demonstrated included small, single-serve candy bags in registered film being filled into clear plastic film at a ratio of 10:1, equating to 90 primary bags/minute and 9 secondary clear bags/minute.

A third application, once again coffee filter pouches, uses a unique sideways-mounted jaw fixture in the upper machine to form filter-paper paper pouches into the round shape to match coffee brewing machine baskets. This means the pouches are oriented vertically as they exit the sideways-turned initial jaws, and must be re-oriented via a transition funnel that twists the bag 90 deg to fit into the lower bag.

In all instances, the two sections are controlled independently via touchscreen HMI, and lengths, temperatures, and seal times are set independently. A clear enclosure allows easy windows into operations to monitor performance and correct any issues.

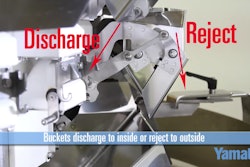

During the demo, attendees asked about ensuring safe transfer from top to bottom bag.

“Transfer is direct— in the top machine, the finished bag is formed nearly inside the top of the forming tube of the bottom machine,” said Stenske. “When the top seals are made and the bags are cut and released, it’s dropping straight down into the second bag. The machines have communication with each other, so the top machine makes the bag, the bottom machine is ready to accept it, and automatically goes through its cycle.”

Other applications include snacks, trail mix, even single-serve pet food. As demonstrated, coffee applications used an auger filler from Spee-Dee.

“Pretty much any product you want to run bag-in-bag, we can do that,” he concludes.

To view the demo in its entirety (available through March 31, 2021), and add Matrix to your MyConnects Planner, click here.

![Cng D Main Navy Blue[4]](https://img.packworld.com/files/base/pmmi/all/image/2020/11/CNG_D_Main_Navy_Blue_4_.5fad4e9934ec7.png?auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=167&q=70&w=250)