When packaging innovation is “dead on,” it does more than just help present a product. It can change how consumers use the product. Inherently, that can put a new spin on an entire product category, building equity for a brand as an innovative leader.

This tactic not only boosts market share, it creates opportunities to build incremental sales by creating usage occasions for a product that previously may not have been possible. When brand managers, designers, and others on the development team work “on the same page” in understanding materials technology and leveraging it, “it will change how people interact with products,” says David Kendall, president at Kendall Ross, a Seattle firm that designs packaging to fit individual retail environments.

Following are several new packages in which technical innovation helps brands to satisfy unmet needs in the marketplace.

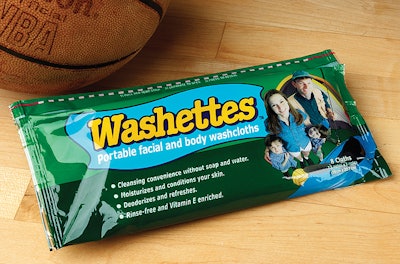

Washettes Portable Washcloths

The innovation: Replacing the larger plastic tubs associated with moist, disposable towelettes with a pocket-size, flexible pouch.

The marketplace: Disposable wipes have flourished as a new product over the past several years, making them one of the fastest-growing categories in the store. It started with moistened, disposable baby wipes that are pulled from a plastic canister, a package that has been around for a generation. But over the past several years, brand managers have been extending the wipes concept to products from household cleaners to towelettes for the automobile.

However, consumers have pointed out some shortcomings with the packages bearing these products. Foremost, they’re too bulky to carry in purses or gym bags. When the package is a plastic construction, it can also break or crush more fragile items in the purse or bag, and some consumers have remarked that the closing mechanism on the plastic containers sometimes fails to securely close the lid. Some consumers have solved the portability issue by taking the extra step of removing a few towelettes from their original packaging and placing them in a small, clear-film bag.

The package: Thantex, Greenville, SC, provides another example that some of the most innovative thinking in package design is coming in private-label goods. For the past four years, the company has manufactured a line of portable, polypropylene, nonwoven, moist washcloths for medical applications. It wanted to extend the line into retail distribution, under the Washettes brand. Thantex needed a more functional package that fits well with consumer lifestyles, and the answer was a flexible pouch holding eight washcloths. The pouch comes from Cadillac Products Packaging, which also printed the package. Thantex filled the pouches in-house.

The package is flexo-printed in four colors and measures 111¼2” x 51¼2”. Many flexible pouches now come with a zipper or slider closing mechanism, but the Washettes package, a 48-ga, three-layer polyester structure, opens by pulling on a red tear strip and then separating the two ends on the top of the package. An adhesive band reseals the package when the two open ends are pressed.

Thantex has identified four different consumer markets for the product: home use, work, camping, and fitness/athletics. While the product remains the same, color-coded pouches and different graphics create a distinct package for each market.

The benefits: Linda Domec-Wiemert, sales and marketing manager, explains two key consumer advantages to the packaging. Foremost is the portable size.

“It’s smaller than the plastic tubs. It fits easily into a gym bag or backpack. When you’re looking at tubs of 48 wipes, that’s hard to fit into a gym bag,” Domec-Wiemert says.

Second, the different packaging colors and graphics reinforce the consumer perception that the company truly understands their needs.

Stagg Chili

The innovation: Using a foil-and-paperboard carton instead of a metal can.

The marketplace: Metal cans are a longtime packaging staple for chili. Like many other product categories in which cans dominate, chili carries a perception among consumers as a somewhat visually dull item in the store aisle.

The package: Hormel Foods, Austin, MN, responded with a retortable carton from Tetra Pak. The package is a paper, plastic, and foil construction that makes the product shelf stable for two years. The carton’s multilayer lamination stabilizes the chili inside the package in the same manner as the traditional canning process.

On the store shelf, the square package gives Stagg Chili a different look amid a sea of round cans. That fosters consumer perceptions of Hormel as an innovative marketer.

With a larger “billboard” than a can to face the consumer, Hormel leverages the square carton’s front panel by answering the trend toward fresh, wholesome products. A banner in the lower portion of the panel proclaims “Preservative Free.”

“Our consumer research showed a clear preference for this new packaging concept,” says Larry Vorpahl, vice president and general manager of grocery products at Hormel Foods.

The benefits: Hormel takes the additional step of instructing consumers how to operate the new packaging. Instructions take the form of red arrows at opposite ends of the carton with the direction to “LIFT.” The top panel rises to expose icons that guide consumers in tearing a laser-scored opening.

Retailers benefit from the square carton shape, too. It sharply reduces the air space between rows of round cans on the shelf, thereby making out-of-stock situations less likely.

Wolfgang Puck Gourmet Mocha Latte

The innovation: Making a hot beverage available anywhere, when the consumer wants it.

The marketplace: From convenience stores to mall kiosks, ready-to-drink coffee has never been more available than now. Recent structural innovations in plastic lids do a better job of protecting against burns from spilled hot beverages. However, consumers still have to visit the point of delivery in order to get ready-to-drink coffee hot.

The package: WP Beverage Partners, Newport Beach, CA, discarded the ubiquitous paperboard cup for its Wolfgang Puck gourmet coffee brand and introduced a high-barrier, self-heating container that fits ergonomically in the hand. It’s shelf stable, so it doesn’t require refrigeration, and it fits in a cup-holder.

The container, created by OnTech, consists of three components provided by Sonoco: a six-layer, blow-molded polypropylene cup and cone, as well as an injection-molded PP actuating “puck.”

The inner cone holds calcium oxide while the outer body of the container holds the beverage. A button on the bottom of the package is pressed to begin heating the 10 oz of beverage inside the package to 145ºF within eight minutes. Lakeside Foods processes the container and American Fuji Seal provides the Plasti-Shield™ shrink label that keeps the heated container cool to the touch.

The benefits: The advent of the paperboard cup and the convenience store stimulated thinking that brought about a wave of on-the-go food and beverage packaging in the past 10 years. The Wolfgang Puck package takes convenience packaging to a higher level by creating “portability on demand.” Bob Groux, WP Beverage Partners chief executive officer, observes that “you don’t have to stop at the coffee shop. You don’t have to wait in line. You pop one open in the driveway and by the time you hit the freeway, you have a hot latte.”

The package functions as a self-brewer that provides a hot cup of coffee wherever and whenever the consumer wants it. The self-heating technology makes this package concept viable for other beverages, such as soup, cocoa and baby formula.