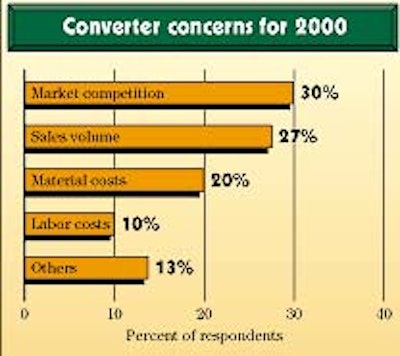

Flexible packaging converters cite a variety of concerns about their business for the year 2000. These were revealed in the Flexible Packaging Assn.’s The State of the Industry Report 2000.

First on converters’ lists (Chart 3) is competition in the market, followed by maintenance of sales volume. However, moving up on this list is the cost of materials, which was cited as the most important concern by two of every 10 converters. This level, says FPA, is the highest in six years.

Meanwhile, labor issues, the most important concern for 10% of converters studied, reached an all-time high level. Not only is this caused by a shortage of workers, converters also are seriously concerned about the skills levels of employees.

Despite both federal and state legislation restricting plant air and water emissions, it’s interesting that government issues did not show up as an important concern for any of the respondents. Perhaps that’s the result of changes in converters’ business practices.

According to the survey, converters’ use of solvents in both inks and adhesives has dramatically declined in the last 10 years (Charts 4 and 5). Since 1990, the use of solvent-based adhesives has dropped from more than 50% of converters to today’s level of 33%. Mean-while, waterborne adhesive use has moved from 32% of converters in ’90 to about 48% in 2000. Both solvent-based and waterborne expect modest growth over the next five years.

Clearly the big winner by 2005 is predicted to be solventless adhesives, now used by only 18% of flexible packaging converters. By 2005, solventless adhesives are expected to be used by a third of all converters. And radiation-cured adhesives, still used by only about 5%—the same level as 10 years ago—is expected to jump fourfold by 2005.

Ink usage shows a similar pattern. In the last 10 years, solvent-based ink usage has slipped from more than 90% of converters to about 82%. During that same period, converters using water-based inks have soared from 20% of converters to 60% today. Looking ahead five years, converters see continued growth in water-based inks to reach about 70% of packaging converters, while solvent-based ink usage is expected to stay the same.

Inks cured by ultraviolet energy, a new technology, is expected to soar from practically no converters today to 22% by 2005.

The survey also covers the issue of consolidation, and, in fact, the report lists the merger and acquisition activity among both converters and suppliers over the last two years. In looking at different routes for expanding their business, converters are targeting international markets more than ever before. Nearly half of those surveyed say they will either expand or build a new overseas plant this year, while just 6% expect to be involved in an international merger or acquisition.

See the main story that goes with this sidebar: Growth accelerates in flexible materials