The AIPIA World Congress, held just before the holidays in 2023, served as a global epicenter for smart packaging technologies. The AIPIA Packaging Challenge held there, now a venerable fixture of the event, gives smart packaging technology suppliers a chance to pitch their solutions to a major brand owner in a lightning round of tailored presentations, each only three minutes. Major brand owner might be underselling it, since this year, Anheuser-Busch InBev was on hand looking to solve problems that only active and intelligent packaging can handle.  (from left) Farida Bensadoun, global engineer, packaging innovation, AB InBev; Eef de Ferrante. managing director, AIPIA; and Luiz Andre Correa, global manager, supply chain of the future (digital innovation), AB In-Bev

(from left) Farida Bensadoun, global engineer, packaging innovation, AB InBev; Eef de Ferrante. managing director, AIPIA; and Luiz Andre Correa, global manager, supply chain of the future (digital innovation), AB In-Bev

Packaging World caught up with the two AB InBev Packaging Challenge judges after the event to see why they chose the winners they did, and what tech stood out to them as viable and scalable. Luiz Andre Correa, global manager, supply chain of the future (digital innovation), and Farida Bensadoun, global engineer, packaging innovation, both of AB InBev, were at the AIPIA World Congress on the hunt for digital and connected packaging solutions. Bensadoun focuses on consumer-facing entertainment and engagement through packaging. Correa is tasked with understanding supply chain challenges, and learning how emergent digital tech can solve them. The pair made good use of the Packaging Challenge stage to vet smart packaging vendors.

“As a packaging innovator, I am always striving to find the best way to make our packaging functional, ergonomic, and appealing to the consumer,” Bensadoun said. “As we see an increase in digitalization, there is an opportunity to bridge the physical to digital through packaging. Packaging’s primary purpose is to protect the product it transports and to interact with the consumer. But packaging is so much more. It’s there to inform the consumer, help differentiate, and bring recognition to the brand. Most of all, it’s an integrating part of the consumer experience. So why not take it to a digital level?”

AB InBev has attended previous AIPIA World Congresses and Correa even spoke at the event in the past. As such, they’ve been able to watch the smart packaging market evolve over the years, chronicling its evolution and cataloging advancements that could scale, even at a massive beverage company like AB InBev. To Bensadoun, November 2023’s event might have been a threshold moment for smart packaging.

“Speakers and companies attending have practical and available solutions that are in-market (or close) that could be implemented in the short term and eventually at scale. We also look at emerging technologies, but there is a need to better understand how we can answer to our consumers’ experience expectations now,” Bensadoun said of this year’s event compared to previous years. “From my point of view, I see that there were more market executions, testing, trials, and practical ways to go forward. I also see a more consolidated way forward on some technologies, like using pack features to identify unique markers of packaging without the need of a dedicated tag—for example Alitheon’s technology [FeaturePrint, which takes a photo of a pack and uses AI to uniquely identify it through existing features rather than applied marks] or Systech’s [packaging coding, product authentication, and traceability tech that combats counterfeiting and diversion].”

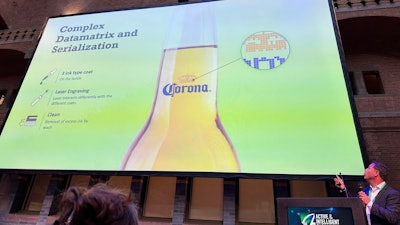

Correa and Bensadoun had four distinct requirements of the Packaging Challenge supplier participants. They came into the challenge knowing that no single supplier could scratch all four itches—as previously discussed, this is just the reality in the nascent world of smart packaging. The first AB InBev requirement related to the 2D datamatrix (QR code), and how to improve readability with smartphones when laser-engraved on clear surfaces, like on beer bottles. Supply chian-scanable and smartphone-readable 2D datamatrix codes from Experience is Everything's pitch to AB InBev.

Supply chian-scanable and smartphone-readable 2D datamatrix codes from Experience is Everything's pitch to AB InBev.

“The presence of 2D codes on-pack is increasing and it’s used in a plethora of applications. As a FMCG business, we have the possibility to use these codes for tracking and tracing, consumer engagement, transparency, etc.,” Bensadoun said. “With datamatrix codes, as you know, more information can be encoded in less space which makes them very attractive. In fact, they can be small yet easily scannable. It’s mainly used in supply chain activity (e.g. asset tracking) and it makes sense to leverage the same code for consumer engagement to prevent multiple codes on pack as this could be confusing for the consumers.”