Since 2015, LiquiForm Group® LLC has been a part of The Packaging Conference agenda, providing updates on its progress toward commercialization. So, it was only fitting that at this year’s TPC, held in Orlando, Feb. 5-7, Ashish Saxena, Vice President and General Manager of LiquiForm, should unveil the first commercial package made with the form/fill process. While Saxena did not reveal the name of the end user, a press release issued the following day provided details on the package, a 12-oz PET bottle for the Nature’s Promise brand of hand soap.

The package was produced on a proprietary, Amcor-built machine powered by the LiquiForm process. Says Amcor, the new machine is the industry’s first manufacturing unit to successfully use LiquiForm. At PACK EXPO Las Vegas 2017, Amcor Limited, the parent company of LiquiForm Group, shared that it had also licensed the technology to four other OEMs and converters to move it forward more rapidly. These include Sidel, KHS Corpoplast, Krones, and Japanese converter Yoshina Kogyosho Co.

For the Nature’s Promise bottle Amcor partnered with GreenBlendz, a Michigan-based co-packer and developer of private-label, environmentally-friendly consumer products. The bottle, which contains 50% post-consumer recycled content, is a drop-in replacement for the former Nature’s Promise container and uses the existing closure and label.

Said Steve Berry, founder and COO of GreenBlendz, in the announcement on the launch, “We’re excited to be a partner in the commercial validation of such a highly sustainable manufacturing process. LiquiForm technology delivers enormous efficiencies throughout the supply chain and improves the industry’s carbon footprint.”

LiquiForm technology uses the packaged product instead of compressed air to simultaneously form and fill containers. In this case, the hand soap essentially forms its own rigid PET container. By combining the forming and filling into one step, the process eliminates costs associated with the equipment and energy of the traditional blow-molding process along with the handling, transport, and warehousing of empty containers.

“LiquiForm has the potential to revolutionize the filling and packaging industries with a more flexible, efficient, and sustainable supply chain,” said Ann O’Hara, Vice President and General Manager of Amcor Rigid Plastics’ Diversified Products Division in the announcement. “The development and launch of the first commercial manufacturing machine and the introduction of the first commercial product represent two major milestones for the LiquiForm technology.”

According to Amcor, the forming of bottles with the LiquiForm process also opens new pathways toward lighter, more sustainable packaging. Lighter-weight containers, achieved through improved consistency in wall thickness, combined with a reduction in the transport of empty containers, reduces environmental emissions and lowers the carbon footprint. The LiquiForm process also offers the potential to reconfigure supply chains and move packaging closer to the market, resulting in strong logistical benefits and further carbon footprint reductions.

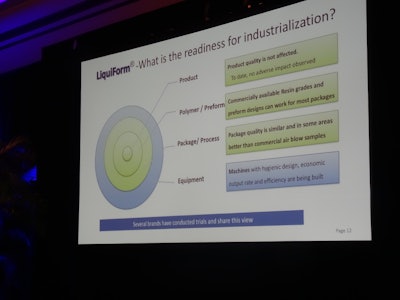

According to Saxena, LiquiForm has worked with most standard resins, as well as most stock preforms, without issue. The process has also been used with a range of product viscosities, including a thick conditioner. “We continue to do more and more work to push the boundaries to make the technology fit for all packages and applications,” he said. “but the good news is that we haven’t hit a wall yet. Our aim is to do even smaller and larger packages.”

As predicted by O’Hara at TPC 2015, commercial momentum for the LiquiForm process is now underway and accelerating. “Interest from Fortune 500 companies is growing by leaps and bounds,” said Saxena. “Almost all of them come away with the impression that liquid forms better than air.”

Read more about the conference at "The Packaging Conference answers, "What's new?'"