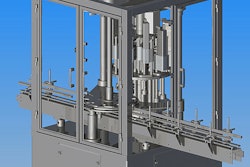

Hassia Verpackungsmaschinen GmbH developed the THS system that thermoforms, fills, and seals the package. The Hassia machine earned a DuPont Silver award. Hassia positions the innovative package as an alternative to injection-molded containers.

“The bottle cup is a design innovation for thermoform, fill, and seal machines because you can use different forming tools to produce different bottle shapes,” he says. “It gives you some flexibility in package design and market uniqueness. On this thermoforming machine you can produce standard yogurt or pudding cups, or various inverted bottle shapes, by changing forming tools. This creates cost savings.”

Ravalli says polyvinyl chloride, polystyrenes, and barrier plastic materials in varying thicknesses can be used to form the inverted bottle-shaped cup. Die-punching creates the opening of the bottle neck. A die-cut aluminum or plastic lid material would then be heat-sealed to the bottle opening. The bottle cup body is decorated with a paper label via an integrated in-mold labeling system, though Hassia points out that it can provide integrated shrink-labeling systems for containers without straight sidewalls. Filling is done through the bottom of the bottle cups, which can then be sealed with aluminum, PET, or PS film. A punching tool can separate packages into single cups, or into sets of 2, 4, 6, etc. Vacuum arms upright the filled cups for downstream case packing.