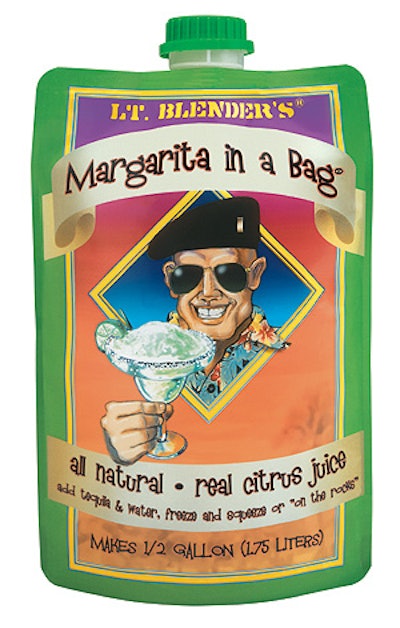

When Ralph McMorris of Yogurt Technologies decided to move from institutional to retail markets with his line of dry mixes for frozen desserts and cocktails, he knew he needed a package that would set his product apart.

“The product has to make an impression on the shelf,” says McMorris, president of the Galveston, TX, firm. “It’s the most important way for us to communicate to prospective customers.”

But it wasn’t just graphics that McMorris was after. Functionality was also a key. The package not only had to contain the dry mix, it also had to be the vessel into which proper amounts of tequila, triple sec, and water could be poured and mixed. Additionally, the package had to be freezer-friendly and needed a dispensing fitment that would let consumers squeeze the blended product out in a frozen slurry state.

After exploring a number of packaging options, the firm decided to package its Lt. Blender’s product in the Kap*Pak™ stand-up pouch from Kapak Corp. Made from a polyester/biaxially oriented nylon/linear low-density polyethylene lamination and sporting a 40-mm threaded spout fitment, the pouch holds 12 oz of dry margarita mix, which sells at retail for $6.00 to $8.00. Lively graphics are produced on Kapak’s eight-color Toshiba GSN 120 press.

Sectional drive technology

The press’s use of sectional drive technology and lightweight cylinders are both worth noting. Sectional drive means that rather than using a single mechanical drive shaft to power all eight print stations, the press relies instead on 16 servo motors governed by a software/PC combination. This electronic as opposed to mechanical control system is inherently superior, so print registration is tight.

“We are very pleased with the way the graphics have turned out,” says McMorris. “We wanted to create a margarita product that was different than anything else currently in the marketplace. Kapak was able to get the job done for us.”

Important as it is, good graphics are not the only benefit gained through sectional drive technology.

“Sectional drive [unbundles] the print stations, which means you run only those stations you need for a job,” says Kapak president Gary Bell. “We can be running a job on stations one through four while we are inking the pans and mounting the cylinders on stations five through eight. This brings huge gains in productivity by greatly reducing time spent on make-ready. It also opens the door to taking on shorter-run jobs that historically would never be done on a gravure press.”

Also helping to keep costs down by adding greater flexibility is Toshiba’s use of hollow, lightweight cylinders weighing about 70 lb each rather than the heavy cylinders typically found on gravure presses. Specialized lifting and moving equipment to remove cylinders is not required.

According to McMorris, feedback generated by the Lt. Blender’s product has been extremely positive.

“The stand-up pouch gives us several ways to present our product,” he adds. “It can be sold standing up on a shelf or hung from a clip rack. What’s more, the pouch format allows twice the amount of product on the shelf when compared to bottled mixes and four to five times the amount compared to some of the larger-sized plastic tubs where the mix is sold in liquid form.”

For now, says McMorris, the pouches are filled manually on an auger filler. “But we’re looking to change that,” he adds, “and Kapak is helping us in that process as we gear up for national distribution.” —PR