This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

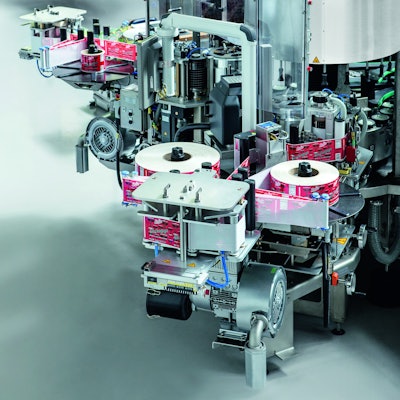

The Innoket 360 and extremely compact Innoket 360 S (with an output of up to 50,000 PET bottles per hour) have now been joined by the Innoket 360 Duo which has two roll-fed labeling stations and a capacity of up to 60,000 non-returnable PET bottles an hour.

All labelers in the Innoket 360 series have also been further optimized. Brand-new developments include a servomotor-driven reel stand and an intelligent sensor which controls label cutting, reacts very quickly to new requirements and can also do without cutting marks (as an option). The Innoket 360 in particular is now even more flexible thanks to the option of integrating an extra self-adhesive labeling station and/or a tamper-evident sleever.

The roll-fed labelers operate with a double reel stand, with film being unraveled from one reel while the other is idle. When the reel comes to an end, the speed drops momentarily and the autosplicer attaches the end of the active reel to the beginning of the waiting reel. Operation then continues without interruption. A sensor-driven web edge control ensures that the labeling material always keeps to its allocated track.

In the past, when the film web was unreeled a mechanical control unit was responsible for yielding the given tension for precise cutting on the labeling station. A servodrive is now employed here, considerably reducing the amount of force exerted on the film web – namely by around 80%. In turn, this boosts machine tolerance to fluctuating grades of label material, making the Innoket 360 series even more robust and even more reliable. Thinner film materials than those previously used can now also be processed.

With the classic cutting mark sensor the new label length had to be taught in on every format changeover. This is no longer necessary. The new sensor reacts to the operator simply touching the product to be processed on screen, resulting in even faster changeovers and fewer sources of error. The optional use of a sensor which no longer needs a cutting mark is another novelty. It can detect precisely where a cut is to be made by studying the label's pixel array. Label ends no longer have to be glued over unattractive cutting marks. In this manner up to 10 mm of label can be saved per labeled bottle.

The proven highlights of KHS' roll-fed labeling machines include the cutting unit equipped with self-sharpening cutters, the slip-free vacuum drum and the induction heater in the gluing drum. The Innoket 360 labeler series thus scores not only on process quality but also on ease of operation, short changeover, maintenance and cleaning times and, as a result, a high degree of machine efficiency.