The 9.3 Micron CO2 laser creates a whitish mark by “foaming” the surface of the bottle, so not only is the mark visible with high contrast, but it can help to eliminate the chance of material penetration and puncture.

When laser coding PET with the standard 10.6 micron CO2 laser, a semi-transparent mark is created that is easy to see up close, but not as legible at a distance. Additionally, when marking PET with the standard 10.6 Micron CO2 laser there is the risk of penetrating the material and causing a puncture and potential leakage.

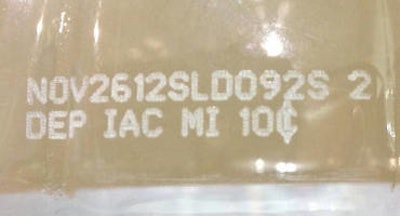

When the two marks are compared side by side, the difference in contrast can easily be seen. The 9.3 micron mark foams the surface, which slightly widens the mark and gives the frosted white appearance. The 10.6 micron mark melts the surface, providing a semi-transparent mark that is narrower.

Depending on the application, higher mark speeds using lower wattage lasers are possible on PET with the 9.3 micron CO2 laser because of these differences and the resulting mark. The combination of 9.3 micron CO2 wavelength and the company’s Crystal Font (Dot Matrix Font) is particularly effective for the high speed marking of PET.